Spoke to Renishaw about a spindle probe, ..

they told me they don't make them anymore, .. only option

is the stand alone Cyclone at $44K, .. not an option for me.

I want to digitize in the spindle, .. so, .. anyone know the

part numbers or model numbers for the Renishaw probe & controller?

Now I'm going to use a Centroid M400 controller, they offer a spindle

digitizer, .. any thoughts or experience?

Thanks,

Curtis

Renishaw spindle probes???

Moderator: Team

Renishaw spindle probes???

Race Flow Development

Simultaneous 5-axis CNC Porting

http://www.raceflowdevelopment.com

Simultaneous 5-axis CNC Porting

http://www.raceflowdevelopment.com

-

SchmidtMotorWorks

- Vendor

- Posts: 11003

- Joined: Mon Apr 11, 2005 2:30 am

- Location: CA

-

SchmidtMotorWorks

- Vendor

- Posts: 11003

- Joined: Mon Apr 11, 2005 2:30 am

- Location: CA

My Mori came with the control box and what looks like some light signal but the rest of the parts were missing. I have been meaning to figure it all out when I have time.

I knew a guy when I worked at HPD that was really into using them for everything like confirming set-ups and measuring after cuts etc. I will send him an email to see if he still works there and has any advice. I will be in Japan for the next 2 to 4 weeks so I might not always have web access (14 hour days, long train rides, fish and rice, etc.).

I knew a guy when I worked at HPD that was really into using them for everything like confirming set-ups and measuring after cuts etc. I will send him an email to see if he still works there and has any advice. I will be in Japan for the next 2 to 4 weeks so I might not always have web access (14 hour days, long train rides, fish and rice, etc.).

-

SchmidtMotorWorks

- Vendor

- Posts: 11003

- Joined: Mon Apr 11, 2005 2:30 am

- Location: CA

Greetings from Japan, I had some waiting to do this morning and found this. Maybe an inexpensive solution?

http://www.maxnc.com/page6.html

http://www.maxnc.com/page6.html

-

CNC BLOCKS

- Guru

- Posts: 4653

- Joined: Thu Jul 01, 2004 6:34 am

- Location: NORTHEAST

- Contact:

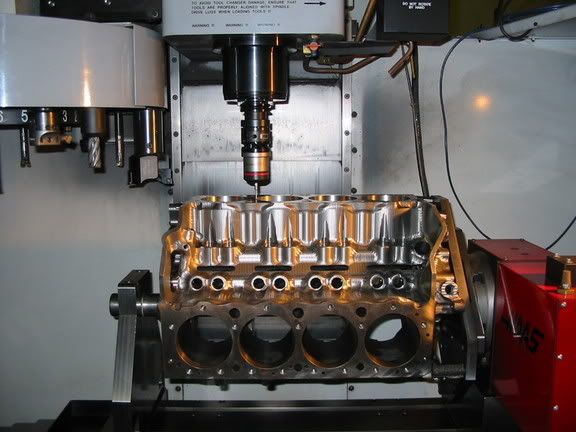

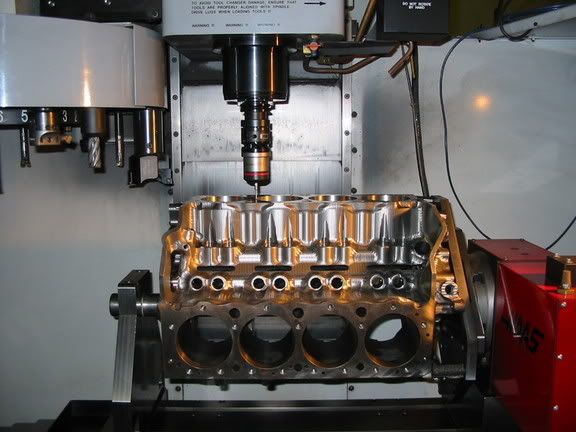

In my CNC machine I use a Marposs probing system seems to work fine for me and is very accurate as we have a progam for checking deck heights, Bore locations in X and Y and cylinder size and on some of the 010 blocks we have to bore them to the preprobed location as the cylinders are off to much to blue print bore. It takes about 5 minutes to run this program.

Here is a pic of the Probe we use

Here is a pic of the Probe we use

Website is up and running

http://hinksonautomotive-cncblocks.com/

Machine shop tour

http://hinksonautomotive-cncblocks.com/shop-tour/

Monthly Specials

http://hinksonautomotive-cncblocks.com/specials/

55MM babbit cam bearings with 1 hole

http://hinksonautomotive-cncblocks.com/

Machine shop tour

http://hinksonautomotive-cncblocks.com/shop-tour/

Monthly Specials

http://hinksonautomotive-cncblocks.com/specials/

55MM babbit cam bearings with 1 hole

-

SchmidtMotorWorks

- Vendor

- Posts: 11003

- Joined: Mon Apr 11, 2005 2:30 am

- Location: CA

-

CNC BLOCKS

- Guru

- Posts: 4653

- Joined: Thu Jul 01, 2004 6:34 am

- Location: NORTHEAST

- Contact:

So far there does not seem to be any issues in that area.SchmidtMotorWorks wrote:Thats a cool setup, do you find that the bell housing face of the block is out of square with the crankshaft bores? If so I guess you must have some way to compensate.

We installed a block in the CNC machine that we fully machined 5 years ago as it has been setting and we had to bush the lifter bores back to standard and the block probed out with in .0012 of what it was done the first time and the decks was with in .0008

Website is up and running

http://hinksonautomotive-cncblocks.com/

Machine shop tour

http://hinksonautomotive-cncblocks.com/shop-tour/

Monthly Specials

http://hinksonautomotive-cncblocks.com/specials/

55MM babbit cam bearings with 1 hole

http://hinksonautomotive-cncblocks.com/

Machine shop tour

http://hinksonautomotive-cncblocks.com/shop-tour/

Monthly Specials

http://hinksonautomotive-cncblocks.com/specials/

55MM babbit cam bearings with 1 hole