My own engine is a Twin cam 4-valve 1.8L turbo, ~8.5:1 CR making 350HP and it loves to fill catch cans while drifting. Engine still compression tests well and shows no signs of knock physically, or on my knock monitor. I've even gone so far as to cut big chunks out of the timing map at the track with no change in the amount of oil it blows out the breathers. AFR's sit around 11-11.5:1 when on the drift track. In my case this is on 94oct RON+MON/2 gas.

Interestingly, the engine does not push oil out the breathers when I'm just rowing through the gears at the road course or on the street. Only sustained high rpm and load.

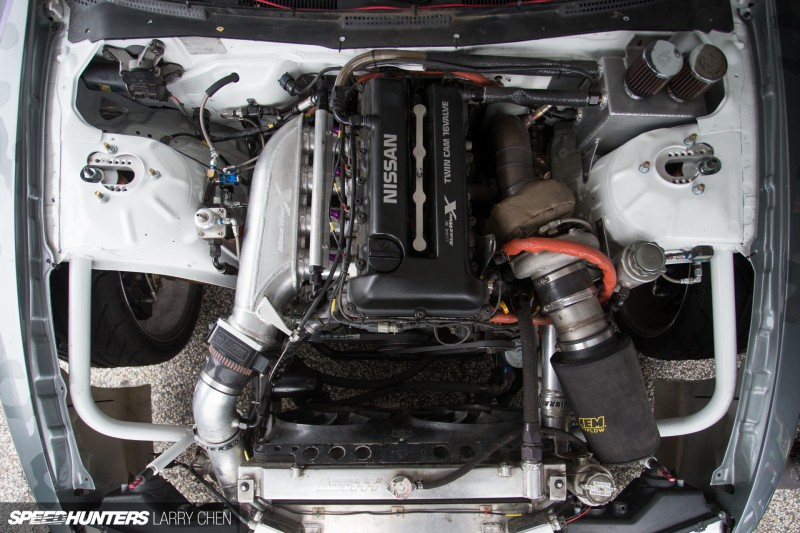

It's become commonplace in the high-level, wet sump, race gas competition builds (Formula Drift) to have high volume catch cans that drain back into the pan. Some examples:

3.4L 2JZ, big "self-draining" catch can. Allegedly capable of 900hp

Boosted LS3, "self-draining" catch can

Big power 2.4L 4banger, Turbo and spray, "self draining" catch can

So what does everybody think? Are we dealing with abnormal levels of blowby for the RPM?

Are we seeing a normal level of blowby that's building up in the crankcase faster than it can vent due to the sustained high RPM? And picking up more windage oil on its way out?

Are the rings starting to flutter and we're holding them at the RPM where they do so, hence losing seal to the cylinder walls?

Thanks for the input all! Been lurking for a while now, it's nice to finally participate.