Rover V16

Moderator: Team

Rover V16

Two V8 blocks bolted together with alum. case for cam gear drive,(2 gear floating idlers/sbc), and accessory drive of 3 stage dry sump and alternator. Megasquirt/or ? for COP and electro inj. Common 3/4" thick alum girdle joining both blocks and gearcase, at deep Y pan rails.. Fire every 45 deg. Rigid join front/rear cranks and cams. Fluid damper at front of engine. Automatic trans. 50 gpm electric coolant pump, rear sprint car 3 row rad. Estimated vehicle weight, dry= 1,400 lbs. +/-. Rather mild 8L. with hyd roller cams. Mostly street, limited drag. Skilled thoughts please ?Thanks, Art.

Re: Rover V16

Could two Rover V8s be coupled? Certainly. Should it be done? Not anything about this makes it a good idea.

The idea of making a V16 by coupling two V8s comes around on a regular basis since there was a V8. The romance of it ignores there are more practical and higher horsepower 8-liter V8s readily available today with less expense and less complication.

So if accomplishing something very difficult for its own sake is the goal, go for it and share your progress. Also, ask Frankenferrari here about the challenges of building one's own engine from previously unassociated bits.

FWIW, while firing every 45 degrees would seem the logical way to go, I have a recollection some tried that back in the day and decided with two V8 cranks coupled, 90 degrees was better.

BTW, here's the right way to do it.

https://hips.hearstapps.com/hmg-prod/am ... size=768:*

jack vines

The idea of making a V16 by coupling two V8s comes around on a regular basis since there was a V8. The romance of it ignores there are more practical and higher horsepower 8-liter V8s readily available today with less expense and less complication.

So if accomplishing something very difficult for its own sake is the goal, go for it and share your progress. Also, ask Frankenferrari here about the challenges of building one's own engine from previously unassociated bits.

FWIW, while firing every 45 degrees would seem the logical way to go, I have a recollection some tried that back in the day and decided with two V8 cranks coupled, 90 degrees was better.

BTW, here's the right way to do it.

https://hips.hearstapps.com/hmg-prod/am ... size=768:*

jack vines

Jack Vines

Studebaker-Packard V8 Limited

Obsolete Engineering

Studebaker-Packard V8 Limited

Obsolete Engineering

Re: Rover V16

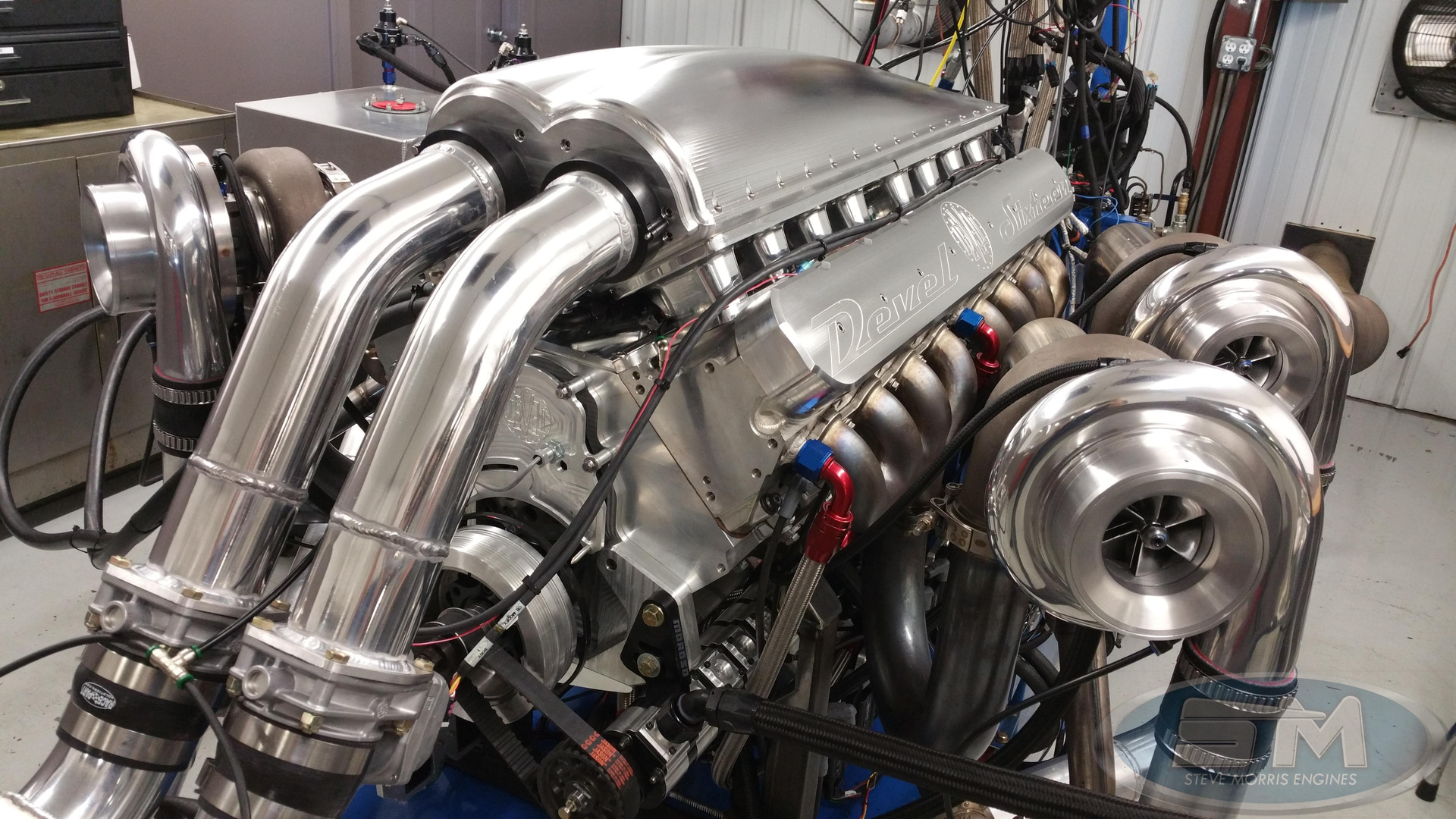

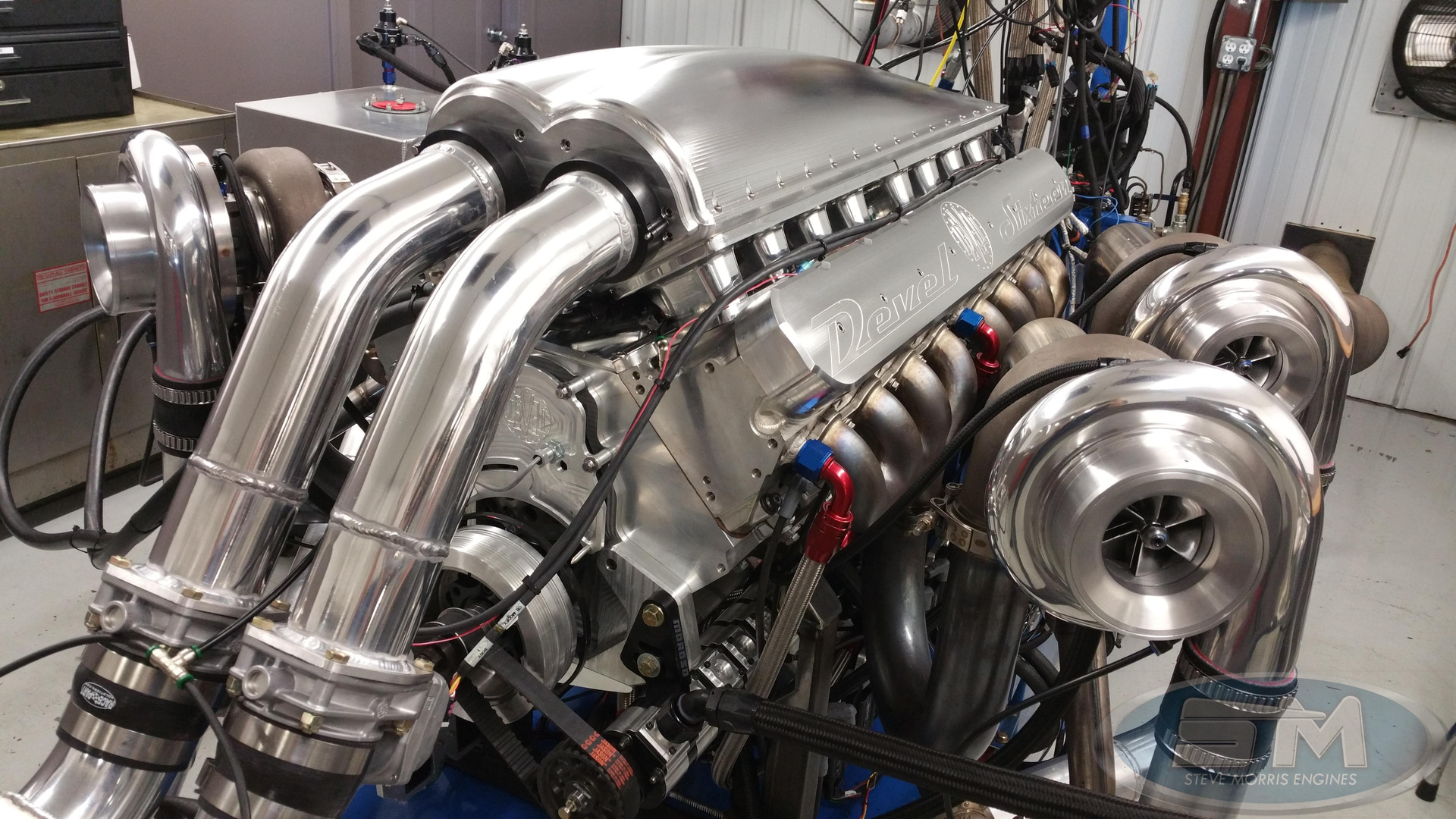

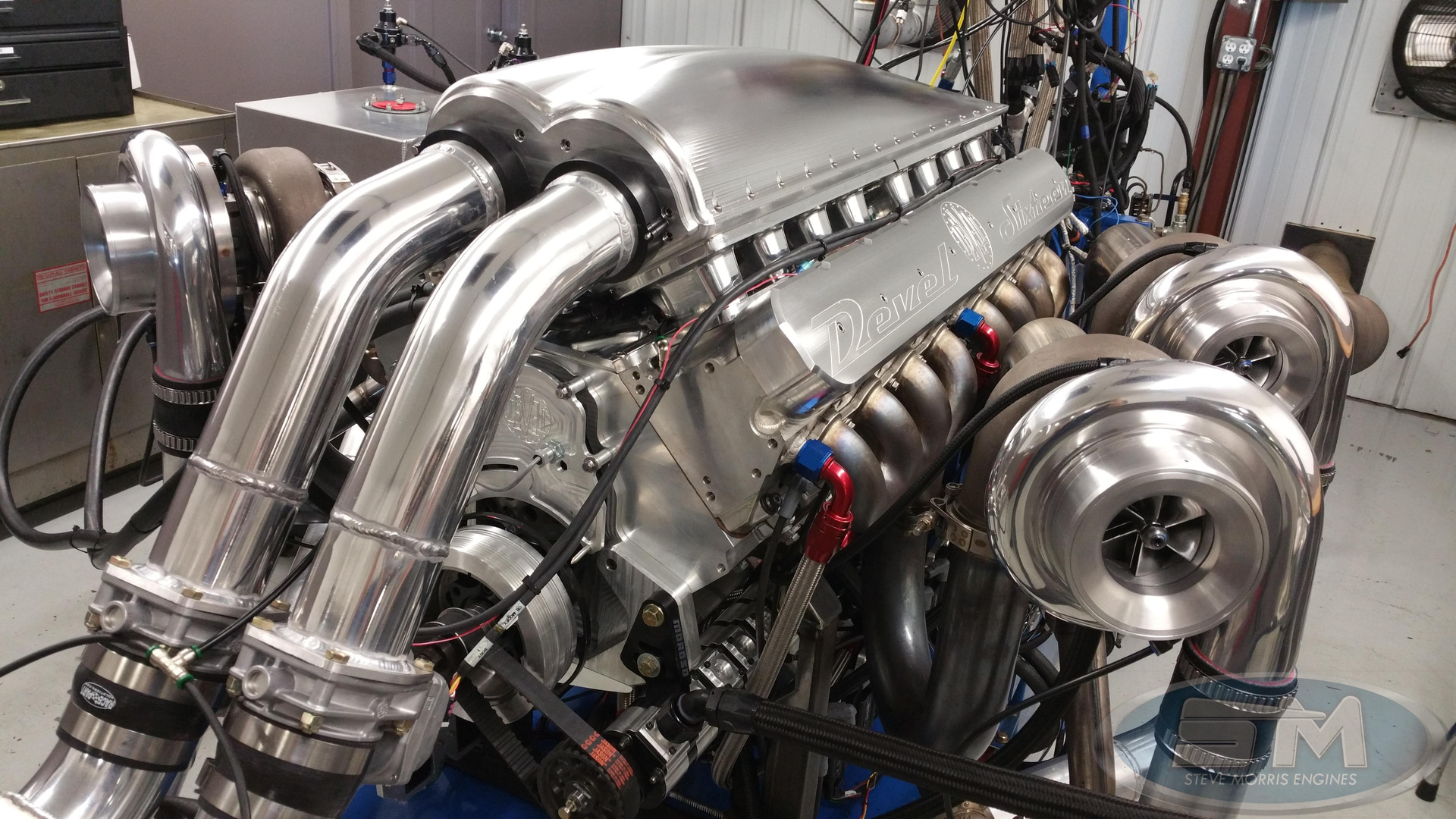

There's also the 5000 hp Devel Sixteen with the quad turbo V16 that Steve Morris designed and built.

https://www.stevemorrisengines.com/engi ... devel-v-16

https://www.stevemorrisengines.com/engi ... devel-v-16

-

Circlotron

- Guru

- Posts: 1141

- Joined: Tue Feb 05, 2013 6:56 am

- Location: Melbourne, Australia

Re: Rover V16

Lets not forget of course, part of the reason for doing this is for what it sounds like

-

englertracing

- Guru

- Posts: 1547

- Joined: Thu Sep 29, 2011 8:55 am

- Location:

Re: Rover V16

I always thought a two three rotors coupled to a large central primary gear between them running a transmission, all mounted transverse, mid engine. In the rear of a light weight class 1 off road race car would be fun.

-

Roundybout

- Pro

- Posts: 397

- Joined: Tue Dec 29, 2015 8:09 pm

- Location: TN

Re: Rover V16

The rigid joining of the crank/cam is the biggest hurdle I believe. That's one long crank and cam. Hanging a fluidampr off the front is a tall task for it. Got to treat it as one long componate though so as rigid as possible. Thinking out loud widdle a one piece billet crank down to where you want the counter weights and treat where they're "joined" as another main bearing between the apapter plate. Same with the cam, just another bearing to support via the plate sandwiched in between.

Re: Rover V16

Doesn't firing 16 cyls at 45 deg., dramatically reduced the force-couple crankshaft harmonics ? At about 500 hp. +/- with 8L.= low stress. Agreed, not the "smartest" design as compared what has been achieved by most on this forum. I greatly appreciate their work. Art.

Re: Rover V16

Back when twin-engine dragsters were a thing, almost everyone used simple chain couplers. Standard industrial-supply shaft couplings.Roundybout wrote: ↑Thu Aug 15, 2019 9:44 amThe rigid joining of the crank/cam is the biggest hurdle I believe.

-

SchmidtMotorWorks

- Vendor

- Posts: 11003

- Joined: Mon Apr 11, 2005 2:30 am

- Location: CA

Re: Rover V16

You will be vastly better off to buy a late model Mercedes or BMW V12 engine from a wrecked car (dirt cheap in So Cal).

Far better engineering and quality in the BMW and Mercedes engines.

Much higher performance potential.

Far better engineering and quality in the BMW and Mercedes engines.

Much higher performance potential.

Helping to Deliver the Promise of Flying Cars

Re: Rover V16

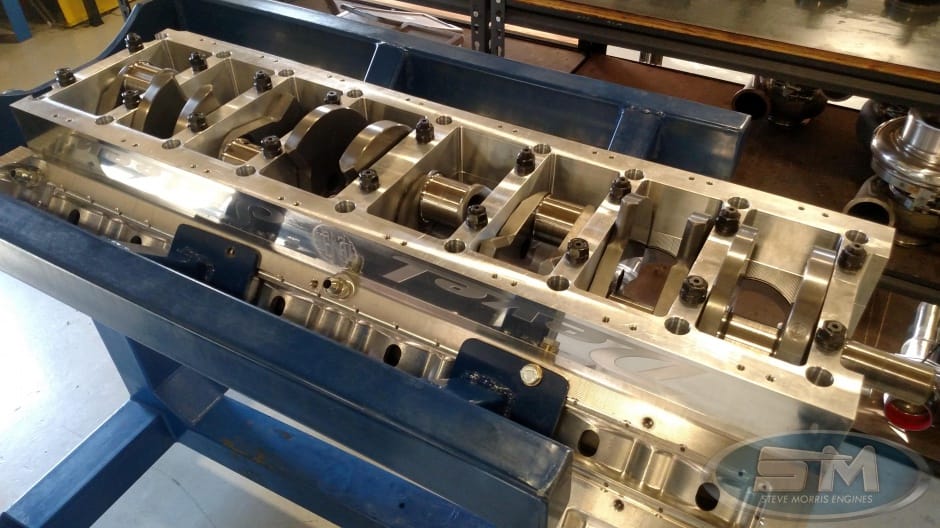

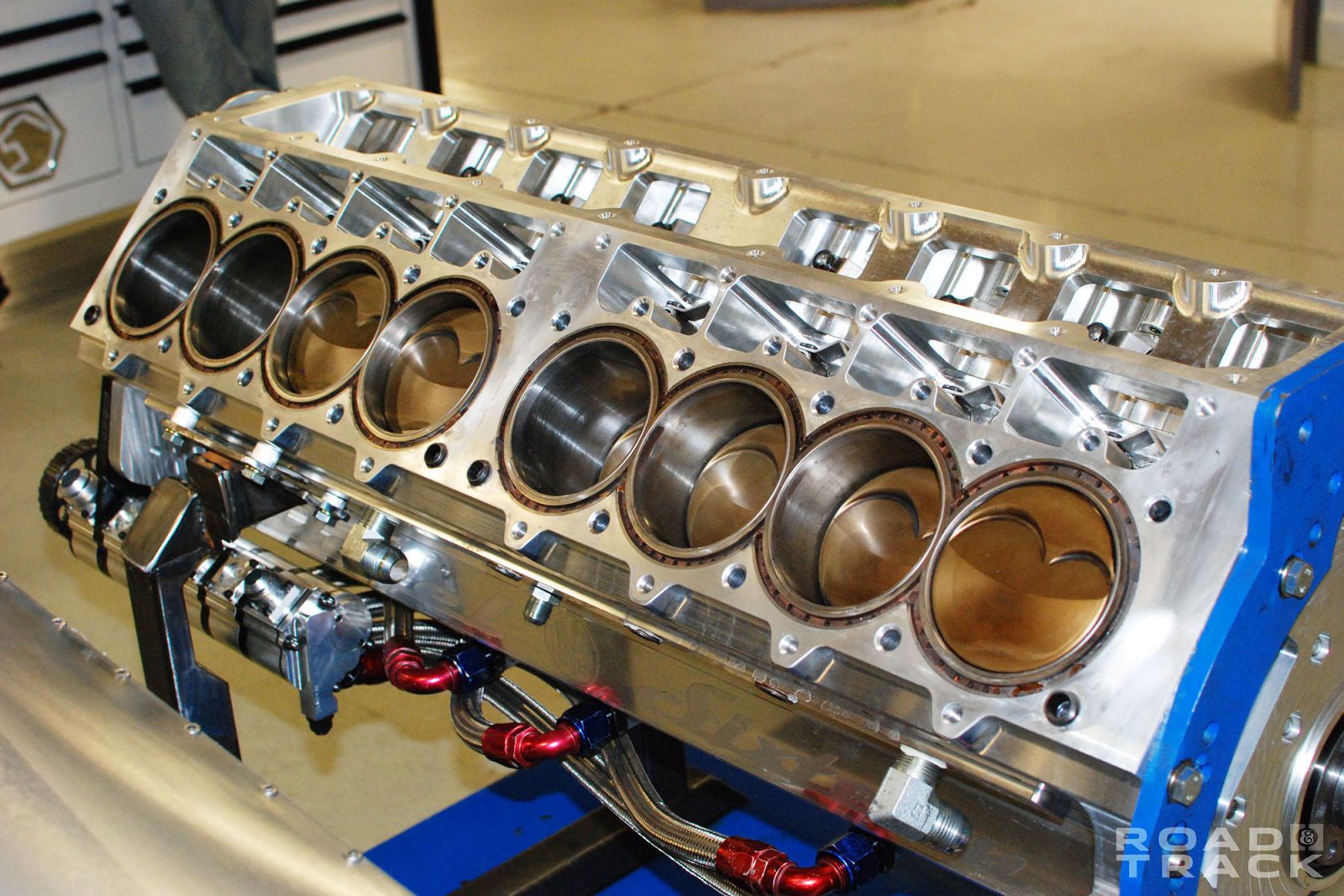

I also found this article, which includes pics of the crank, block, and a few other things. They talk about what went into designing the engine, including the solid billet crank and how they used a center thrust bearing like found in Ford engines between the 2 sets of 8 cylinders instead of just a rear thrust bearing. It incorporates features from Ford engines, big & small block chevies, as well as ls engines and is not just 2 LS V8'S joined at the crank.WoundUp wrote: ↑Wed Aug 14, 2019 10:28 pm There's also the 5000 hp Devel Sixteen with the quad turbo V16 that Steve Morris designed and built.

https://www.stevemorrisengines.com/engi ... devel-v-16

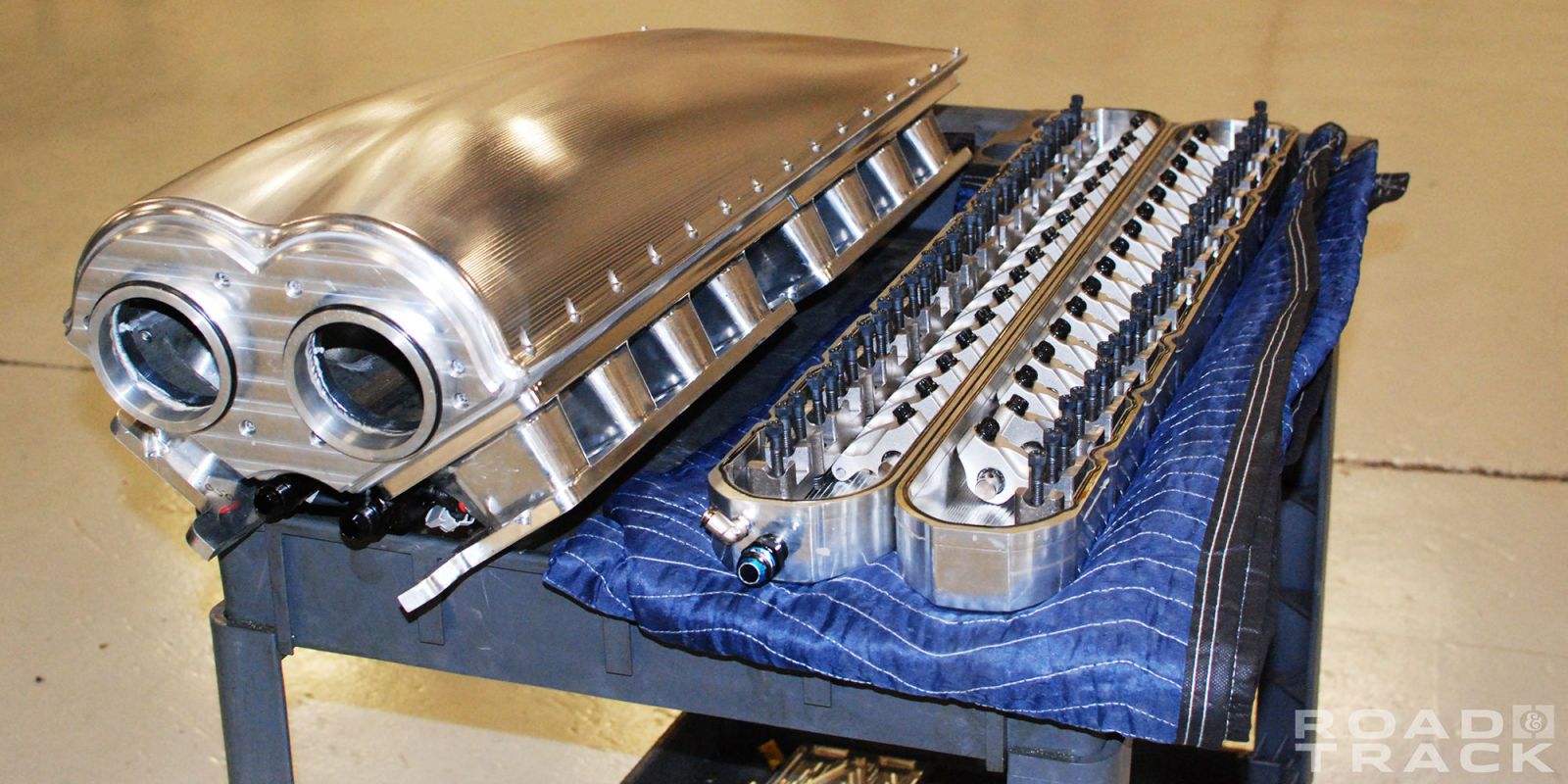

These first few pics are from Steve's website at the first link I posted

Pic of the main caps/girdle combo. 1 solid piece with no loose, individual main caps.

The following pics and article are what I mentioned above

https://www.roadandtrack.com/new-cars/a ... s-engines/

Re: Rover V16

Bench racing aside this has been the undoing of most of these types of projects.

Torsional crank harmonics ('shake') will usually tear apart most 'rigid' couplings, including meshing gears, after any reasonable amount of running even with some sort of intervening 'shock absorber' ...... good luck fitting such a reliable device into your envelope.

The example above used a one piece crank ...... wonder why?

The bigger the bore/stroke and the lower the rpm, the worse it often is, 'hammer blows' I read somewhere ....... search 'Coventry Climax Flat 16' for what you're up against if serious.