20th century manifold reconfigured for 21st century

Moderator: Team

- Dave Koehler

- Vendor

- Posts: 7206

- Joined: Mon Oct 04, 2004 11:19 pm

- Location: Urbana, IL USA

- Contact:

Re: 20th century manifold reconfigured for 21st century

Trucked,

With proper welding I don't see a problem.

However

INLINE 6

IF it was a real big deal then I would make a race manifold for pulling season and swap out as needed.

I do think I should point out that using a working tractor to compete is not realistic or financially feasible.

Similar to cars you just can't be top dog at both, particularly in a rules limited class.

Perhaps buy a second identical tractor and make a no holds barred race vehicle pushing the rules to the limit.

With proper welding I don't see a problem.

However

INLINE 6

IF it was a real big deal then I would make a race manifold for pulling season and swap out as needed.

I do think I should point out that using a working tractor to compete is not realistic or financially feasible.

Similar to cars you just can't be top dog at both, particularly in a rules limited class.

Perhaps buy a second identical tractor and make a no holds barred race vehicle pushing the rules to the limit.

Dave Koehler - Koehler Injection

Enderle Fuel Injection - Nitrous Charger - Balancing - Nitrous Master software

http://www.koehlerinjection.com

"Never let a race car know that you are in a hurry."

Enderle Fuel Injection - Nitrous Charger - Balancing - Nitrous Master software

http://www.koehlerinjection.com

"Never let a race car know that you are in a hurry."

Re: 20th century manifold reconfigured for 21st century

Scott, Tom Langdon's split manifolds are an excellent design and are cast with a high steel content and can be welded if need be. They are set up for twin 2-1/4" exhaust pipes......

I am planning on running a set on the 292 I am swapping into my '57 Chevy. My main concern is whether the rear exhaust drop will work in my chassis. It drops right where all the mechanical clutch linkage is located on my '57 Chevy. I might be able to use the rear piece of the Langdon manifolds if I convert to hydraulic clutch (and it will clear an external slave cylinder...... I don't particularly like the internal type that fit inside the bellhousing).

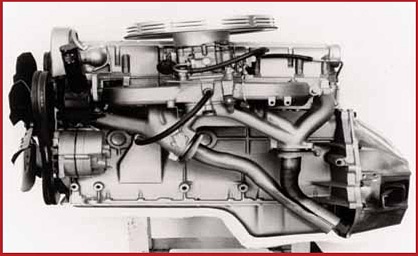

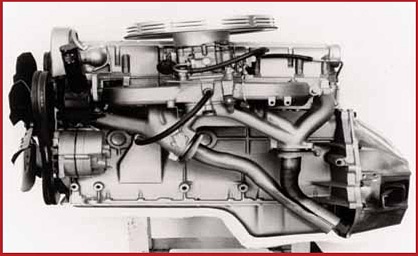

Plan B would be to use the front half of the Langdon split manifold and cut the rear half of the heavy duty Chevy 292 dump truck manifold I have here off and braze it shut where the cut was made. This has a 3-bolt 2-1/2" exhaust flange and would relocate the rear exhaust drop forward a bit (centered on #4 and #5 siamesed exhaust outlets rather than the #6 outlet as the Langdon rear piece does). If it will help with the clutch linkage, I may go that route. My dump truck manifold is made like this one. Note position of exhaust outlet......

The set of Langdon split manifolds I bought were uncoated. They are nice castings and have high steel content if you ever need to weld them. Mine had the flange bolt holes drilled a bit offset from being centered, so I brazed big block Chevy heat risers onto the outlets after gutting the shaft and blade rather than rework the original 2-bolt flanges.

This gave me 2-1/2" 3-bolt outlet flanges and being on the cusp of needing to step up to 2-1/2" dual exhaust anyway, I went ahead and upsized. I am retired and don't have the right stuff here to weld cast-iron, so that's why I used an oxy-acetylene torch with a #4 tip and brazed them, using yellow brass rod and Albro flux. Besides, last time I brazed anything like this was back in 1976 aboard ship and I wanted to see if I could still do it.

Tom Lowe at 12-bolt.com is the go to guy for Tom Langdon's exhaust manifolds now......

https://www.12bolt.com/

He also has used manifolds. The first image here is of a dual exhaust manifold from a 292 in a John Deere combine......

https://www.12bolt.com/store/p186/Used_ ... 0-292.html

There are also the Pontiac OHC Sprint engines which had a dual exhaust manifold. These are very close to the Chevy regarding design and fitup. With a few small adjustments, they are said to be a good fit on Chevy inline 6s......

Good luck with your search,

Harry

I am planning on running a set on the 292 I am swapping into my '57 Chevy. My main concern is whether the rear exhaust drop will work in my chassis. It drops right where all the mechanical clutch linkage is located on my '57 Chevy. I might be able to use the rear piece of the Langdon manifolds if I convert to hydraulic clutch (and it will clear an external slave cylinder...... I don't particularly like the internal type that fit inside the bellhousing).

Plan B would be to use the front half of the Langdon split manifold and cut the rear half of the heavy duty Chevy 292 dump truck manifold I have here off and braze it shut where the cut was made. This has a 3-bolt 2-1/2" exhaust flange and would relocate the rear exhaust drop forward a bit (centered on #4 and #5 siamesed exhaust outlets rather than the #6 outlet as the Langdon rear piece does). If it will help with the clutch linkage, I may go that route. My dump truck manifold is made like this one. Note position of exhaust outlet......

The set of Langdon split manifolds I bought were uncoated. They are nice castings and have high steel content if you ever need to weld them. Mine had the flange bolt holes drilled a bit offset from being centered, so I brazed big block Chevy heat risers onto the outlets after gutting the shaft and blade rather than rework the original 2-bolt flanges.

This gave me 2-1/2" 3-bolt outlet flanges and being on the cusp of needing to step up to 2-1/2" dual exhaust anyway, I went ahead and upsized. I am retired and don't have the right stuff here to weld cast-iron, so that's why I used an oxy-acetylene torch with a #4 tip and brazed them, using yellow brass rod and Albro flux. Besides, last time I brazed anything like this was back in 1976 aboard ship and I wanted to see if I could still do it.

Tom Lowe at 12-bolt.com is the go to guy for Tom Langdon's exhaust manifolds now......

https://www.12bolt.com/

He also has used manifolds. The first image here is of a dual exhaust manifold from a 292 in a John Deere combine......

https://www.12bolt.com/store/p186/Used_ ... 0-292.html

There are also the Pontiac OHC Sprint engines which had a dual exhaust manifold. These are very close to the Chevy regarding design and fitup. With a few small adjustments, they are said to be a good fit on Chevy inline 6s......

Good luck with your search,

Harry

Re: 20th century manifold reconfigured for 21st century

I'll be up front, some of Langdon's products are good but in my opinion he will try to steer you down a path that favors what he sells.Lowe is a decent guy that will actually share tune info unlike langdon..On My Chevy 261's and GMC 302 inline 6's I prefered to make my own tube headers.The 3/8 flanges are usually available on Ebay for not much money...Is used 1-1/2 pipe on the end ports and 1-5/8 on the siamese ports,about 16 inch long into a collector and a single 2-1/2 pipe system...I never cared for the sound of duals on an inline 6..

Most of the 292 stock cast intakes I saw on bigger trucks were cracked, Most of the GMC 270-302 stock cast exhausts are cracked...The two piece cast exhaust manifolds are a better idea...

I also built a modifed Chevy 153, not a Iron Duke, 4 cylinder for my 47 Willys CJ2 Jeep...And a 292 for my 69 Chevy PU...I tighted up the quench to about .040 on both and it really improved throttle response and fuel mileage. I also did the quench on a 261 Chevy and the GMC 302. Did full time vacuum for the advance limited to about 12 degrees and as much initial and mechanical advance as the engine would tolerate, about 34 total on the 153 and 292.The 292 has 9-1 propane pistons,the tight quench, a mild Schnieder cam, and ran ok on 89 octane pump gas in the 3700 pound truck with 3.73 gears and manual trans.The inline guys were ignoring this stuff,very old school....I learned it from the Chevy V8 tuners.. .

.

Most of the 292 stock cast intakes I saw on bigger trucks were cracked, Most of the GMC 270-302 stock cast exhausts are cracked...The two piece cast exhaust manifolds are a better idea...

I also built a modifed Chevy 153, not a Iron Duke, 4 cylinder for my 47 Willys CJ2 Jeep...And a 292 for my 69 Chevy PU...I tighted up the quench to about .040 on both and it really improved throttle response and fuel mileage. I also did the quench on a 261 Chevy and the GMC 302. Did full time vacuum for the advance limited to about 12 degrees and as much initial and mechanical advance as the engine would tolerate, about 34 total on the 153 and 292.The 292 has 9-1 propane pistons,the tight quench, a mild Schnieder cam, and ran ok on 89 octane pump gas in the 3700 pound truck with 3.73 gears and manual trans.The inline guys were ignoring this stuff,very old school....I learned it from the Chevy V8 tuners..

Motorcycle land speed racing... wearing animal hides and clinging to vibrating oily machines propelled by fire

Re: 20th century manifold reconfigured for 21st century

Hiya, Tony! I hear ya! Yes, I am putting the 292 together pretty much as you did yours. Paying close attention to static and dynamic comp. ratios, quench and cam timing. A buddy gave me one of those Dyno 2003 computer programs many moons ago, so I went over several manufacurers' cam lobe profiles online looking to optimize cam specs for what I want this engine to do. The '57 will be used like truck more often than not and will occasionally haul a boat trailer

This dyno program isn't anything like PipeMax. Makes no recommendations, but it is useful after plugging in flow figures for head in comparing results from one cam grind to the other and you can play around with comp. ratio, valve lift and duration, LSA and cam advance/retard to see if there is anything to be gained.

As you know, the long stroke 292 is not a high RPM engine (3.875" bore X 4.10" stroke) and is breathing limited due to 283 sized bore which limits valve size. Rev it much higher than 5,000 RPMs with the super heavy stock rods and pistons and it gets into bad harmonics and wants to sling flywheels.

I will be running lighter pistons and rods that are 1/2 lb. lighter per throw (so 3 lbs. of reciprocating weight shed there) and have set a redline just under where the bad harmonics usually set in with these engines. And just as at EMC with Dan's hemi, ignored big peak HP and TQ numbers and worked at getting the most average power within the engine's operating range (broad powerband rather than peaky with higher peak power numbers).

Also elected to keep valve lift at max of 0.500", as I am running relatively short duration along with big block 1.75:1 Chevy rockers. The idea being to lift and close the valves quickly, but not beat up the valvetrain on a road car doing it. With the good flow numbers of a reworked Sissel lump ported head, there was no real advantage to lifting the valves higher nor adding as much as 30 degrees duration in cam timing (yes, I played with them all). So I went for the least duration and lift needed to achieve my goals in a 9.5:1 engine having right at 7.9:1 DCR.

As it worked out, my cam specs are for a solid lifter flat tappet cam having exhaust lobes from the old 1950s Isky E-4 cam and intake lobes that are only very slightly milder to tighten up DCR. So I called up Isky and had them grind me one on 108 degree LSA. Should be a stump puller in the 292 and idle fairly smoothly (only 42 degrees overlap). Predicted TQ show to have around 330 ft./lb. at 2,000 RPMs and keep a nearly linear torque curve through 4,500 RPMs with peak of 350 ft./lbs. at 3,800 RPMs and dropping only 15 ft./lb. at 4,500 RPMs and another 32 ft./lb. by 5,000 RPMs.

Predicted HP is a shallow curve peaking at 285 HP (flat) between 4,500 - 5,000 RPMs, dropping only 20 HP on either side of peak at 4,000 RPMs and 5,500 RPMs and another 30 HP at 3,500 RPMs and 6,000 RPMs respectively. Granted, these are only predictions and this computer dyno program has no options reflecting the Weber carbs and and large bore dual exhaust system I will be running. So actual numbers will vary. But I believe that if I redline it at 5,000 RPMs with peak TQ at 3,800 RPMs I think it will do what I need it to do in the '57. Especially when towing. And I do have an overdrive tranny for cruising unloaded at highway speeds, which is why I designed this engine for low and mid-range torque, mainly.

At the other extreme...... The solid lifter cam I designed for best power at peak had 244 degrees duration at 0.050" and 0.544" lift ground on 107 degree LSA. Would have made a great short track cam. Made about 35 HP and 30 more ft./lb. at peak, but gave away 40 HP and 50 ft./lb. in the lower RPM ranges where this engine will spend 95% of its time. It did not make equal HP and TQ to the cam grind I went with until revved over 4,500 RPMs. Power really shot up from that point, but the only way to achieve it was to rev the engine way past the point where bad harmonics do a number on Chevy inline 6's. So that's why I went with the mild cam grind.

Regarding the exhaust note, It may sound a bit 'different' than most Chevy 6-bangers. I scrounged some NOS 'Vette sidepipe innards and a few other lengths of pipe (all of them 2-1/2" inner core) having the late '60s 'chambered exhaust' and will cut them up and incorporate them into my undercar exhaust when I weld it together. No mufflers unless its too loud and if it is, I'll either experiment with Helmholtz chambers (nodes) or add a resonator to each side.

I went with the Langdon split manifolds mainly because header leaks on a driver are just no fun at all. Especially at my age. Hell, I have to use two canes just to get around now of days. Figured they would seal better than tube headers. I am only running duals because I have limited space on the '57 where the pipes must pass through the arches in the frame brackets that the bell housing mounts bolt to......

Even then, ground clearance will bear watching. I did the math and I could run both 2-1/2" head pipes into a single 3" pipe and it would be sufficient. But I got a good deal on some mandrel bent 2-1/2" dual exhaust tailpipes by Flowmaster off e-bay. So I'm thinking I'll run 2-1/2" duals but tie both sides together with an H-type balance pipe just behind the gearbox and the transmission crossmember I will add. Together with the bellhousing mounts and front mounts, that will give me a 5-point mounting system. I have done this with V-8s in these cars and it works well.

Best regards and l'shana tovah tikatevu to you and yours my friend,

Harry

This dyno program isn't anything like PipeMax. Makes no recommendations, but it is useful after plugging in flow figures for head in comparing results from one cam grind to the other and you can play around with comp. ratio, valve lift and duration, LSA and cam advance/retard to see if there is anything to be gained.

As you know, the long stroke 292 is not a high RPM engine (3.875" bore X 4.10" stroke) and is breathing limited due to 283 sized bore which limits valve size. Rev it much higher than 5,000 RPMs with the super heavy stock rods and pistons and it gets into bad harmonics and wants to sling flywheels.

I will be running lighter pistons and rods that are 1/2 lb. lighter per throw (so 3 lbs. of reciprocating weight shed there) and have set a redline just under where the bad harmonics usually set in with these engines. And just as at EMC with Dan's hemi, ignored big peak HP and TQ numbers and worked at getting the most average power within the engine's operating range (broad powerband rather than peaky with higher peak power numbers).

Also elected to keep valve lift at max of 0.500", as I am running relatively short duration along with big block 1.75:1 Chevy rockers. The idea being to lift and close the valves quickly, but not beat up the valvetrain on a road car doing it. With the good flow numbers of a reworked Sissel lump ported head, there was no real advantage to lifting the valves higher nor adding as much as 30 degrees duration in cam timing (yes, I played with them all). So I went for the least duration and lift needed to achieve my goals in a 9.5:1 engine having right at 7.9:1 DCR.

As it worked out, my cam specs are for a solid lifter flat tappet cam having exhaust lobes from the old 1950s Isky E-4 cam and intake lobes that are only very slightly milder to tighten up DCR. So I called up Isky and had them grind me one on 108 degree LSA. Should be a stump puller in the 292 and idle fairly smoothly (only 42 degrees overlap). Predicted TQ show to have around 330 ft./lb. at 2,000 RPMs and keep a nearly linear torque curve through 4,500 RPMs with peak of 350 ft./lbs. at 3,800 RPMs and dropping only 15 ft./lb. at 4,500 RPMs and another 32 ft./lb. by 5,000 RPMs.

Predicted HP is a shallow curve peaking at 285 HP (flat) between 4,500 - 5,000 RPMs, dropping only 20 HP on either side of peak at 4,000 RPMs and 5,500 RPMs and another 30 HP at 3,500 RPMs and 6,000 RPMs respectively. Granted, these are only predictions and this computer dyno program has no options reflecting the Weber carbs and and large bore dual exhaust system I will be running. So actual numbers will vary. But I believe that if I redline it at 5,000 RPMs with peak TQ at 3,800 RPMs I think it will do what I need it to do in the '57. Especially when towing. And I do have an overdrive tranny for cruising unloaded at highway speeds, which is why I designed this engine for low and mid-range torque, mainly.

At the other extreme...... The solid lifter cam I designed for best power at peak had 244 degrees duration at 0.050" and 0.544" lift ground on 107 degree LSA. Would have made a great short track cam. Made about 35 HP and 30 more ft./lb. at peak, but gave away 40 HP and 50 ft./lb. in the lower RPM ranges where this engine will spend 95% of its time. It did not make equal HP and TQ to the cam grind I went with until revved over 4,500 RPMs. Power really shot up from that point, but the only way to achieve it was to rev the engine way past the point where bad harmonics do a number on Chevy inline 6's. So that's why I went with the mild cam grind.

Regarding the exhaust note, It may sound a bit 'different' than most Chevy 6-bangers. I scrounged some NOS 'Vette sidepipe innards and a few other lengths of pipe (all of them 2-1/2" inner core) having the late '60s 'chambered exhaust' and will cut them up and incorporate them into my undercar exhaust when I weld it together. No mufflers unless its too loud and if it is, I'll either experiment with Helmholtz chambers (nodes) or add a resonator to each side.

I went with the Langdon split manifolds mainly because header leaks on a driver are just no fun at all. Especially at my age. Hell, I have to use two canes just to get around now of days. Figured they would seal better than tube headers. I am only running duals because I have limited space on the '57 where the pipes must pass through the arches in the frame brackets that the bell housing mounts bolt to......

Even then, ground clearance will bear watching. I did the math and I could run both 2-1/2" head pipes into a single 3" pipe and it would be sufficient. But I got a good deal on some mandrel bent 2-1/2" dual exhaust tailpipes by Flowmaster off e-bay. So I'm thinking I'll run 2-1/2" duals but tie both sides together with an H-type balance pipe just behind the gearbox and the transmission crossmember I will add. Together with the bellhousing mounts and front mounts, that will give me a 5-point mounting system. I have done this with V-8s in these cars and it works well.

Best regards and l'shana tovah tikatevu to you and yours my friend,

Harry

Re: 20th century manifold reconfigured for 21st century

Ha, I had my DNA tested a few months ago to find I'm 46% Ashkenazi Jew.... I never knew.....

Motorcycle land speed racing... wearing animal hides and clinging to vibrating oily machines propelled by fire

Re: 20th century manifold reconfigured for 21st century

Harry and Tony,

Thank you so much for the information. Really appreciate all the insight. I am also dimpling the intake valves figure it will react well to the carburetor and low lift flow. The engine in current state really only likes 20 degrees of timing max. I run plug adapters to run a modern 14mm automotive plug. I plan to do some playing on the dyno to see what it likes best. I like this type of modification as it is just bolt on. I have a adjustable main jet that I can play with too. This engine will really lug and kick out some good numbers if you richen it up a bit.

Here is my custom Gibtech pistons and rods rebushed for a .927 pin. I did a reversed dish of the chamber, its 20cc. Not a ton of quench but hopefully enough.

Oh can some one measure a 292 on how long the exhaust bolts are front to back? And runner center lines for #1 to #2-3 ports?

Thanks again,

Scott

Thank you so much for the information. Really appreciate all the insight. I am also dimpling the intake valves figure it will react well to the carburetor and low lift flow. The engine in current state really only likes 20 degrees of timing max. I run plug adapters to run a modern 14mm automotive plug. I plan to do some playing on the dyno to see what it likes best. I like this type of modification as it is just bolt on. I have a adjustable main jet that I can play with too. This engine will really lug and kick out some good numbers if you richen it up a bit.

Here is my custom Gibtech pistons and rods rebushed for a .927 pin. I did a reversed dish of the chamber, its 20cc. Not a ton of quench but hopefully enough.

Oh can some one measure a 292 on how long the exhaust bolts are front to back? And runner center lines for #1 to #2-3 ports?

Thanks again,

Scott

You do not have the required permissions to view the files attached to this post.

Tractor Puller, 1959 IH 460 with 430cid NA Alcohol Inline 6 started its life as a D282

The only replacement for displacement is RPM!

The only replacement for displacement is RPM!

Re: 20th century manifold reconfigured for 21st century

And here I thought our family had intermarried with the Ashkenazi when one branch left Spain and Portugal after the expulsion of 1492 and moved North through Europe, settling in Elsass on the French/German border.

The surprise for me was the branch on Mom's side who left Persia 1,500 years ago and settled in what is now Azerbaijan. These guys......

https://en.wikipedia.org/wiki/Mountain_Jews

The other surprise was...... 12% Scandinavian. Dad's folks were Scots and Irish on his Dad's side and English on his Mom's side. Turns out these English are the Normans who came to England from France with Wilhelm the Conqueror in 1066. The Normans were Vikings. The French king gave them what is now Normandy to settle in with the promise that they would fight any other Vikings who attempted to either raid or settle in France. Something my wife dug up during her genealogy research.

If I'm still around for the next census, I reckon I'll just say 'Heinz 57' for ethnicity.

Best regards,

Harry

Re: 20th century manifold reconfigured for 21st century

don't want to weld it?

fair enough

ok braze it.

fair enough

ok braze it.

Re: 20th century manifold reconfigured for 21st century

Nice looking pistons, Scott! Should work well for you. I like one off stuff such as this. Much more interesting than the cookie cutter small block Chevy builds.

I measured my 292 exhaust manifold just now. Had to eyeball it using a scale rule because #2 & #3 ports are siamesed on my manifold (one rectangular opening 3" wide). I get 7.5" from center of #1 exhaust port to center of #2 & #3 ports, give or take 0.060".

Regarding length of bolts (or studs)...... That can vary, as you need to measure depth of threaded holes in your head and thickness of the nubs cast into intake and exhaust manifolds. Then there are the thick cupped OEM type steel pieces and the length of threads needed to get full thread engagement when using one of several types of lock washer between cupped piece and nut (if using studs) or underside of bolt head.

The other variable is...... Some folks elect to use thick flat washers instead of the thick cupped OEM pieces. Also...... At each end of the exhaust manifold is a hole that is meant for a screw-in dowel. This aids in hanging the heavy stock cast-iron intake and exhaust manifold combo on the head whilst screwing in the bolts by hand before tightening them. I may forego the studs and substitute bolts or studs there.

Hope this helps,

Harry

P.S. >>> There are some pretty nice turbo exhaust manifolds available for the Chevy inline 6's. Just in case you might want to add some boost to your engine one of these days.

Re: 20th century manifold reconfigured for 21st century

Harry,enigma57 wrote: ↑Tue Oct 01, 2019 9:04 pmNice looking pistons, Scott! Should work well for you. I like one off stuff such as this. Much more interesting than the cookie cutter small block Chevy builds.

I measured my 292 exhaust manifold just now. Had to eyeball it using a scale rule because #2 & #3 ports are siamesed on my manifold (one rectangular opening 3" wide). I get 7.5" from center of #1 exhaust port to center of #2 & #3 ports, give or take 0.060".

Regarding length of bolts (or studs)...... That can vary, as you need to measure depth of threaded holes in your head and thickness of the nubs cast into intake and exhaust manifolds. Then there are the thick cupped OEM type steel pieces and the length of threads needed to get full thread engagement when using one of several types of lock washer between cupped piece and nut (if using studs) or underside of bolt head.

The other variable is...... Some folks elect to use thick flat washers instead of the thick cupped OEM pieces. Also...... At each end of the exhaust manifold is a hole that is meant for a screw-in dowel. This aids in hanging the heavy stock cast-iron intake and exhaust manifold combo on the head whilst screwing in the bolts by hand before tightening them. I may forego the studs and substitute bolts or studs there.

Hope this helps,

Harry

P.S. >>> There are some pretty nice turbo exhaust manifolds available for the Chevy inline 6's. Just in case you might want to add some boost to your engine one of these days.

This International Harvester head is a bit bigger. I'm getting 9" between #1 and #3&4 ports. It maybe was not clear but I was looking for the dimension of bolt centers from front to back, this one is 27 5/8" from front bolt to back bolt on approx center. I imagine the 292 is much shorter.

Here is another picture of me cc'ing the chamber over the weekend. Looks like I need to mill a bit more off.

Thanks,

Scott

You do not have the required permissions to view the files attached to this post.

Tractor Puller, 1959 IH 460 with 430cid NA Alcohol Inline 6 started its life as a D282

The only replacement for displacement is RPM!

The only replacement for displacement is RPM!

Re: 20th century manifold reconfigured for 21st century

Regarding the manifold design. Does it keep 456 pipe separate from the 123 until near the factory flange? Ie could you mill the flange down until it had two holes, one from the front 3 and one from the rear three?

Remember that 4, 5, & 6 fire 240 crank degrees apart and don't really need a separate pipe for flow reasons as there's only one exhaust valve open at a time, the same with 1, 2, & 3. All you can really do is make the junctions nice and make a secondary pipe long enough that the exhaust blowdown from one end of the engine can't interfere with the end of the exhaust stroke from the other end.

Remember that 4, 5, & 6 fire 240 crank degrees apart and don't really need a separate pipe for flow reasons as there's only one exhaust valve open at a time, the same with 1, 2, & 3. All you can really do is make the junctions nice and make a secondary pipe long enough that the exhaust blowdown from one end of the engine can't interfere with the end of the exhaust stroke from the other end.

Re: 20th century manifold reconfigured for 21st century

So a update engine is built and broke in, it made 90pto hp @1800rpm, factory was 75pto hp with a larger carb at 2300rpm. I have my manifold design to try next here are my prototypes to try. The temperatures are from the dyno at full load on a cool day, it was 48 degrees F air temperature.

You do not have the required permissions to view the files attached to this post.

Tractor Puller, 1959 IH 460 with 430cid NA Alcohol Inline 6 started its life as a D282

The only replacement for displacement is RPM!

The only replacement for displacement is RPM!

Re: 20th century manifold reconfigured for 21st century

Happy Motoring,

Harry

Re: 20th century manifold reconfigured for 21st century

Thanks Harry!

I go back and fourth if the pipes are to small. The one is 1-1/8 od 12-14" in length that step into a 1.5" collector. The other 3 are 1-1/4 od 12-14" in length that step into a 1.5 or 1.75" collector.

My carb is only 1-1/8 and red line rpm is 1800. So we will see I guess. My dyno guy is available again either this weekend or next.

I go back and fourth if the pipes are to small. The one is 1-1/8 od 12-14" in length that step into a 1.5" collector. The other 3 are 1-1/4 od 12-14" in length that step into a 1.5 or 1.75" collector.

My carb is only 1-1/8 and red line rpm is 1800. So we will see I guess. My dyno guy is available again either this weekend or next.

Tractor Puller, 1959 IH 460 with 430cid NA Alcohol Inline 6 started its life as a D282

The only replacement for displacement is RPM!

The only replacement for displacement is RPM!