Shop with profilometer in the DC Metro/VA/MD/WV/DE area

Moderator: Team

-

The Dark Side of Will

- Expert

- Posts: 617

- Joined: Wed Feb 18, 2009 2:06 pm

- Location: In the Darkness, where Fear and Knowing are one

- Contact:

Shop with profilometer in the DC Metro/VA/MD/WV/DE area

Is there a shop in the DC Metro area, VA, MD, WV, DE or even southern PA who can use a profilometer to verify surface finish after honing? How about diamond stones?

The engine is a Caddy Northstar. I've been working on it for years, but between a year in Iraq, a year in Afghanistan, some employment instability in between, life gets in the way of cars.

I've had *TWO* failed hone jobs on the block thus far. They resulted in high oil consumption. The bore is out from the stock 3.662 to 3.670. Total Seal has a set at 3.682, so I think that's my next size.

The problem seems to be that the Northstar bore liners are centrifugally case grey iron and are thus VERY hard... like twice as hard as nodular iron.

The first attempt was at a basic Chevy shop that had no idea how to hone a hard block.

For the second attempt, I even bought my own aluminum oxide stones. The result looked not bad, but the shop didn't have a profilometer to double check. It was bad, and that's obvious now that I've torn the engine down again. That shop did a bunch of Subaru work, but I guess Subaru liners (or Darton liners?) aren't that hard either.

Diamond stones would probably do better, but they're pretty srs bzns.

I made my own torque plate and will bring it along with the block.

Takers? Suggestions?

The engine is a Caddy Northstar. I've been working on it for years, but between a year in Iraq, a year in Afghanistan, some employment instability in between, life gets in the way of cars.

I've had *TWO* failed hone jobs on the block thus far. They resulted in high oil consumption. The bore is out from the stock 3.662 to 3.670. Total Seal has a set at 3.682, so I think that's my next size.

The problem seems to be that the Northstar bore liners are centrifugally case grey iron and are thus VERY hard... like twice as hard as nodular iron.

The first attempt was at a basic Chevy shop that had no idea how to hone a hard block.

For the second attempt, I even bought my own aluminum oxide stones. The result looked not bad, but the shop didn't have a profilometer to double check. It was bad, and that's obvious now that I've torn the engine down again. That shop did a bunch of Subaru work, but I guess Subaru liners (or Darton liners?) aren't that hard either.

Diamond stones would probably do better, but they're pretty srs bzns.

I made my own torque plate and will bring it along with the block.

Takers? Suggestions?

-

jake197000

- Expert

- Posts: 546

- Joined: Sun Mar 18, 2012 11:37 pm

- Location:

-

BillK

- Guru

- Posts: 1756

- Joined: Wed Aug 26, 2009 8:30 pm

- Location: Beautiful Southern Maryland

- Contact:

Re: Shop with profilometer in the DC Metro/VA/MD/WV/DE area

First of all are you sure that the problem is not partially if not entirely because the cylinders are .008" oversize now " The stock bore is 93mm which is 3.6614" Unless you are replacing pistons with oversize that is way to much clearance for rings to be expected to compensate for. The pistons must be rocking like crazy. 3.682 would be even worse.The Dark Side of Will wrote: ↑Mon Oct 28, 2019 4:26 pm The bore is out from the stock 3.662 to 3.670. Total Seal has a set at 3.682, so I think that's my next size.

That being said I have never had the pleasure of boring or honing one so I don't know how they are to hone. I do know that there is no way I would touch yours (or any other block that was that far oversize) without boring it first and having new pistons.

Bill Koustenis

Advanced Automotive Machine

Waldorf Md

www.enginerepairshop.com

Advanced Automotive Machine

Waldorf Md

www.enginerepairshop.com

-

The Dark Side of Will

- Expert

- Posts: 617

- Joined: Wed Feb 18, 2009 2:06 pm

- Location: In the Darkness, where Fear and Knowing are one

- Contact:

Re: Shop with profilometer in the DC Metro/VA/MD/WV/DE area

Yes, I had CPs cut for that bore size; I gapped the rings at that bore size, etc.BillK wrote: ↑Mon Oct 28, 2019 8:59 pmFirst of all are you sure that the problem is not partially if not entirely because the cylinders are .008" oversize now " The stock bore is 93mm which is 3.6614" Unless you are replacing pistons with oversize that is way to much clearance for rings to be expected to compensate for. The pistons must be rocking like crazy. 3.682 would be even worse.The Dark Side of Will wrote: ↑Mon Oct 28, 2019 4:26 pm The bore is out from the stock 3.662 to 3.670. Total Seal has a set at 3.682, so I think that's my next size.

That being said I have never had the pleasure of boring or honing one so I don't know how they are to hone. I do know that there is no way I would touch yours (or any other block that was that far oversize) without boring it first and having new pistons.

Once I find a shop that can hit the bore finish, I'll have another set of pistons & rings made, shop will have pistons in hand to finish the bores, I'll gap the rings at that bore size, etc. again.

I'll get a photo of the current state of the bores uploaded.

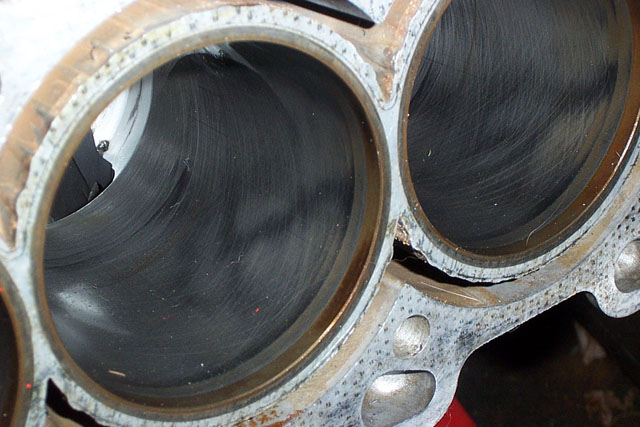

ETA: Here's the FIRST failed hone job:

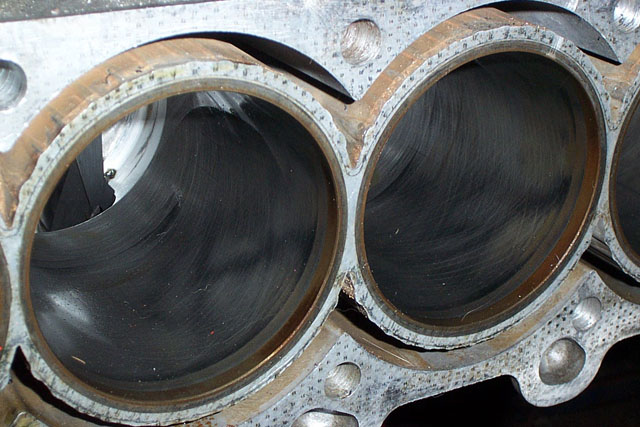

Heres the SECOND failed hone job that is now current (BEFORE assembly):

Will upload a photo I took of the block as it currently sits.

The big question remains: Who has a profilometer to verify bore finish?

- midnightbluS10

- Expert

- Posts: 933

- Joined: Sun Oct 20, 2013 8:41 am

- Location: Shreveport, LA

Re: Shop with profilometer in the DC Metro/VA/MD/WV/DE area

I'd call this place first. They have some nice equipment, including a Kodak optical comparator so I would assume they had a profilometer. Never hurts to call and ask.

http://www.profilemachineworks.com/

http://www.profilemachineworks.com/

JC -

bigjoe1 wrote:By the way, I had a long talk with Harold(Brookshire) last year at the PRI show. We met at the airport and he told me everything he knew about everything.It was a nice visit. JOE SHERMAN RACING

Re: Shop with profilometer in the DC Metro/VA/MD/WV/DE area

looks patchy and smeary.

try shortened 512 stones for base finish, plateau with 623

i don't recall having any problem with those, they might be harder than average, but not the hardest.

try shortened 512 stones for base finish, plateau with 623

i don't recall having any problem with those, they might be harder than average, but not the hardest.

Re: Shop with profilometer in the DC Metro/VA/MD/WV/DE area

I am located in York Pa, and I have a profilometer. Let me know if I can help.

717-252-4293

717-252-4293

“If I hit you with this you’re going to be numb, that’s why they call them numb-chucks “Si Robertson

Re: Shop with profilometer in the DC Metro/VA/MD/WV/DE area

Interesting... they're about a 45-minute drive south of me, although I don't see myself needing to do any business with them.midnightbluS10 wrote: ↑Tue Oct 29, 2019 8:47 pm I'd call this place first. They have some nice equipment, including a Kodak optical comparator so I would assume they had a profilometer. Never hurts to call and ask.

http://www.profilemachineworks.com/

-

The Dark Side of Will

- Expert

- Posts: 617

- Joined: Wed Feb 18, 2009 2:06 pm

- Location: In the Darkness, where Fear and Knowing are one

- Contact:

Re: Shop with profilometer in the DC Metro/VA/MD/WV/DE area

Thanks! I emailed them to see if they do engine work. There are lots of job-shops that can do aerospace work in the DC area, but not a lot of engine shops.midnightbluS10 wrote: ↑Tue Oct 29, 2019 8:47 pm I'd call this place first. They have some nice equipment, including a Kodak optical comparator so I would assume they had a profilometer. Never hurts to call and ask.

http://www.profilemachineworks.com/

PM sent

PM sent.

Re: Shop with profilometer in the DC Metro/VA/MD/WV/DE area

I don't need a PM, thanks tho. Really no secrets to it.

I am sure I have honed a few of those engines but specifically I don't remember much about it.

The jobs that come back are the ones you end up remembering, and how I learned what NOT to do.

I am sure I have honed a few of those engines but specifically I don't remember much about it.

The jobs that come back are the ones you end up remembering, and how I learned what NOT to do.