Page 1 of 1

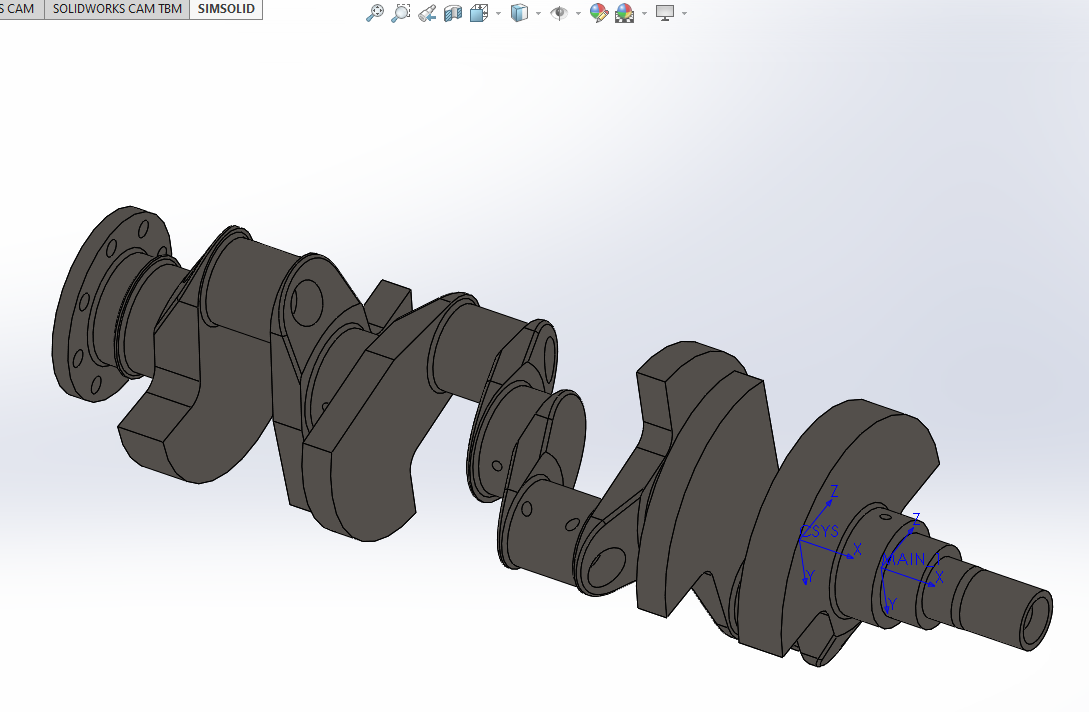

Mopar RB Crank Journal Spacing

Posted: Sun Nov 10, 2019 5:09 pm

by Rick!

Does anyone know if distance between main journals 4 and 5 is the same as between journals 1 and 2?

I've got a two piece crank and a vernier and it's not quite the right equipment to make the measurements so I can complete the CAD model of it.

Thanks.

Re: Mopar RB Crank Journal Spacing

Posted: Sun Nov 10, 2019 8:53 pm

by BillK

Rick,

I have several cranks at the shop. I will try to remember to measure a couple of them in the morning.

Re: Mopar RB Crank Journal Spacing

Posted: Sun Nov 10, 2019 10:21 pm

by SchmidtMotorWorks

Most Race cranks are.

The OEM stuff was all over the place.

Re: Mopar RB Crank Journal Spacing

Posted: Mon Nov 11, 2019 10:58 am

by Diodedog

What is a two piece crank and why not just check the mains in the block, if the spacing is different on the crank the block will be spaced accordingly.

Re: Mopar RB Crank Journal Spacing

Posted: Sat Nov 16, 2019 4:39 pm

by Rick!

BillK wrote: ↑Sun Nov 10, 2019 8:53 pm

Rick,

I have several cranks at the shop. I will try to remember to measure a couple of them in the morning.

Thanks for the measurements, Bill, much obliged.

Diodedog, "two-piece" is another way of saying broken crank. The block, along with a new Bryant billet crank, is in Immokalee this weekend.

Re: Mopar RB Crank Journal Spacing

Posted: Tue Nov 19, 2019 1:43 am

by SchmidtMotorWorks

Rick! wrote: ↑Sat Nov 16, 2019 4:39 pm

BillK wrote: ↑Sun Nov 10, 2019 8:53 pm

Rick,

I have several cranks at the shop. I will try to remember to measure a couple of them in the morning.

Thanks for the measurements, Bill, much obliged.

Diodedog, "two-piece" is another way of saying broken crank. The block, along with a new Bryant billet crank, is in Immokalee this weekend.

What is your goal?

To make one?

Re: Mopar RB Crank Journal Spacing

Posted: Tue Nov 19, 2019 7:41 am

by Rick!

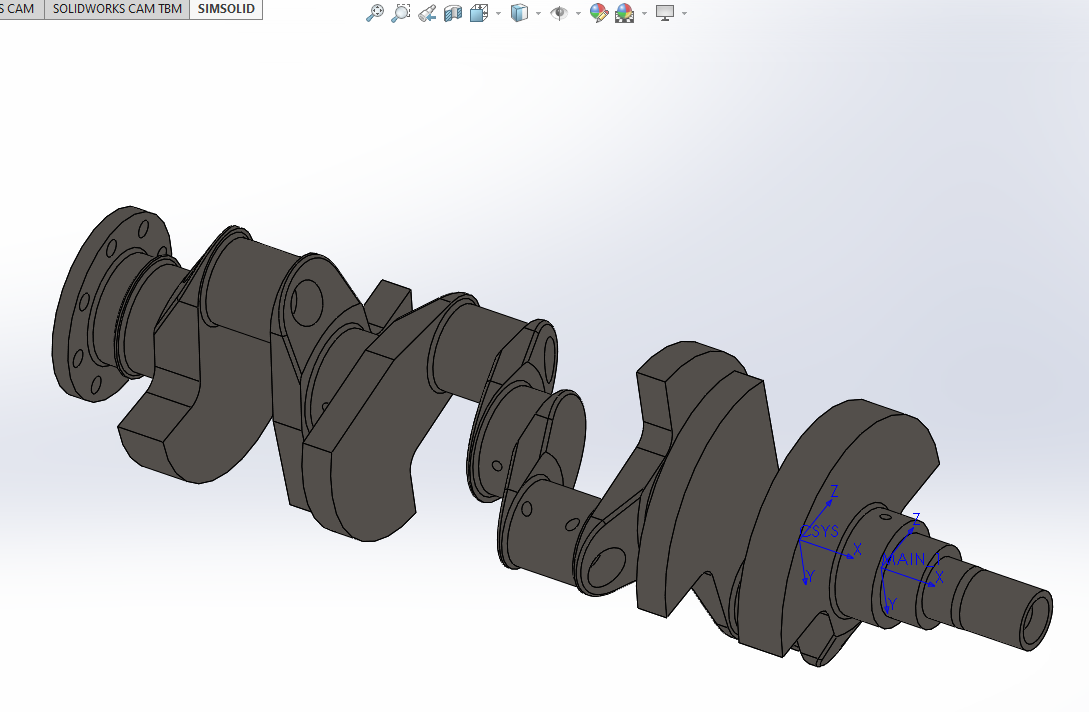

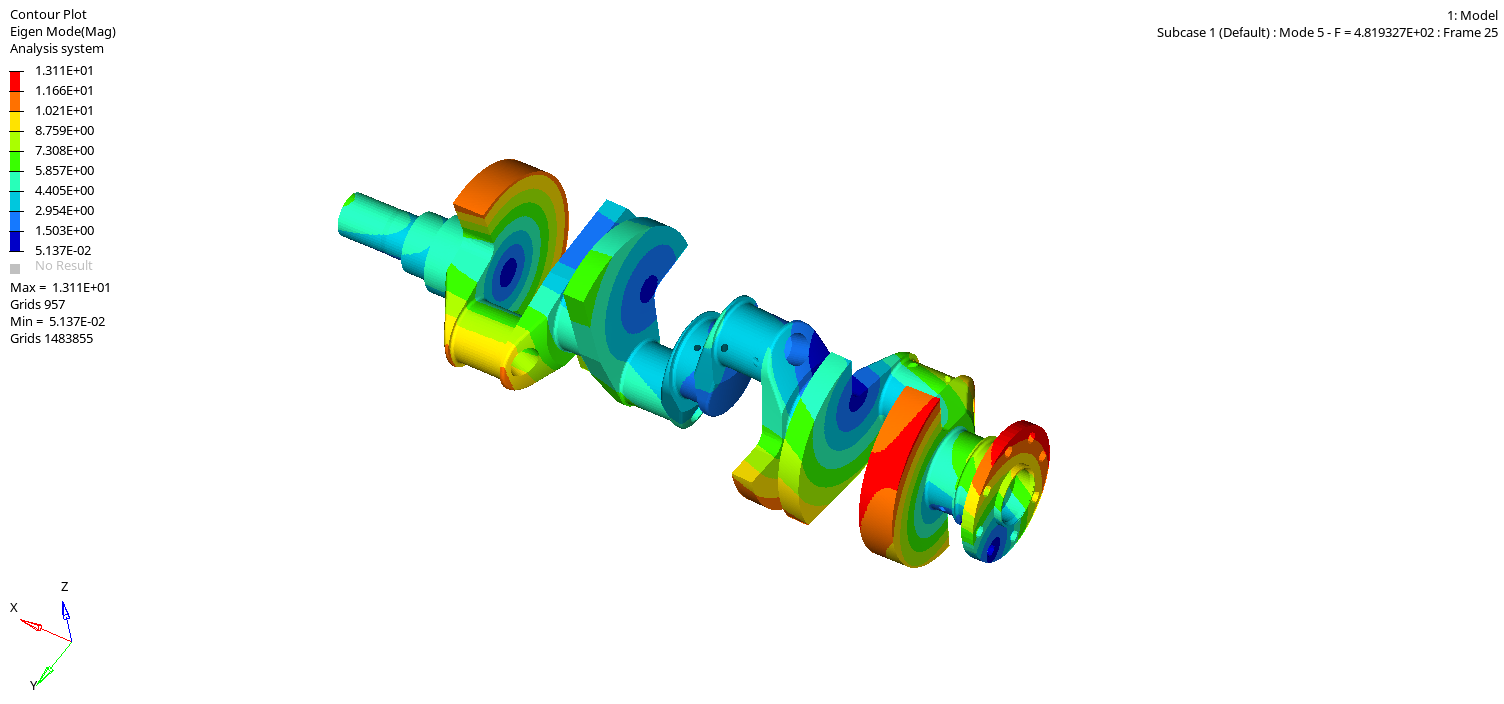

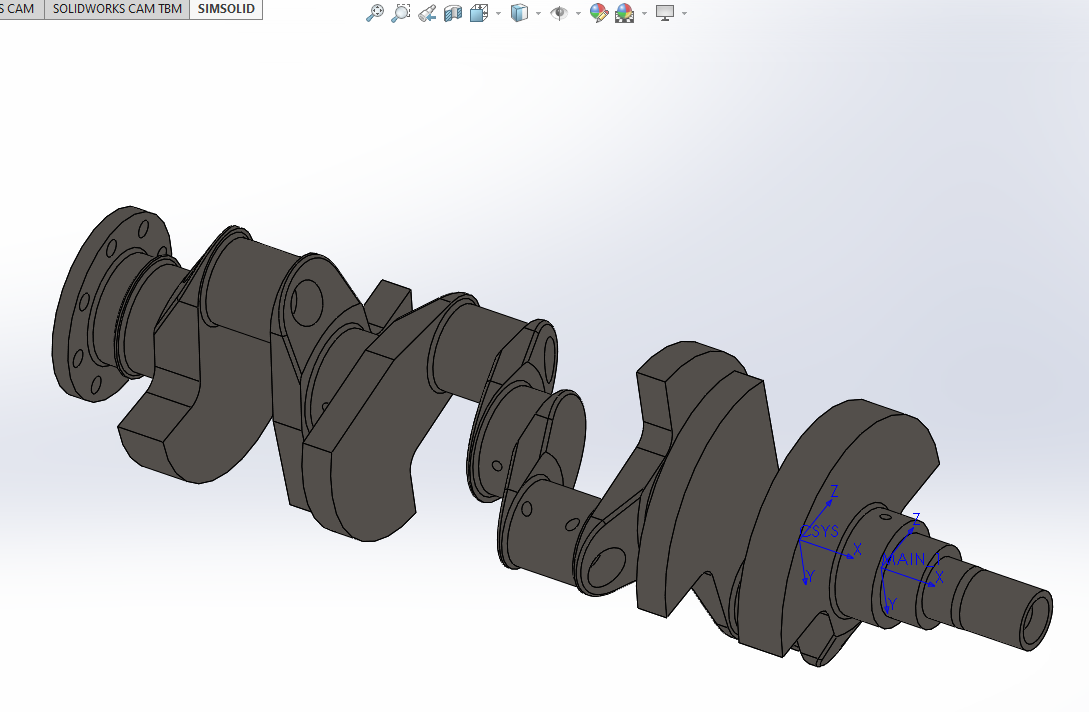

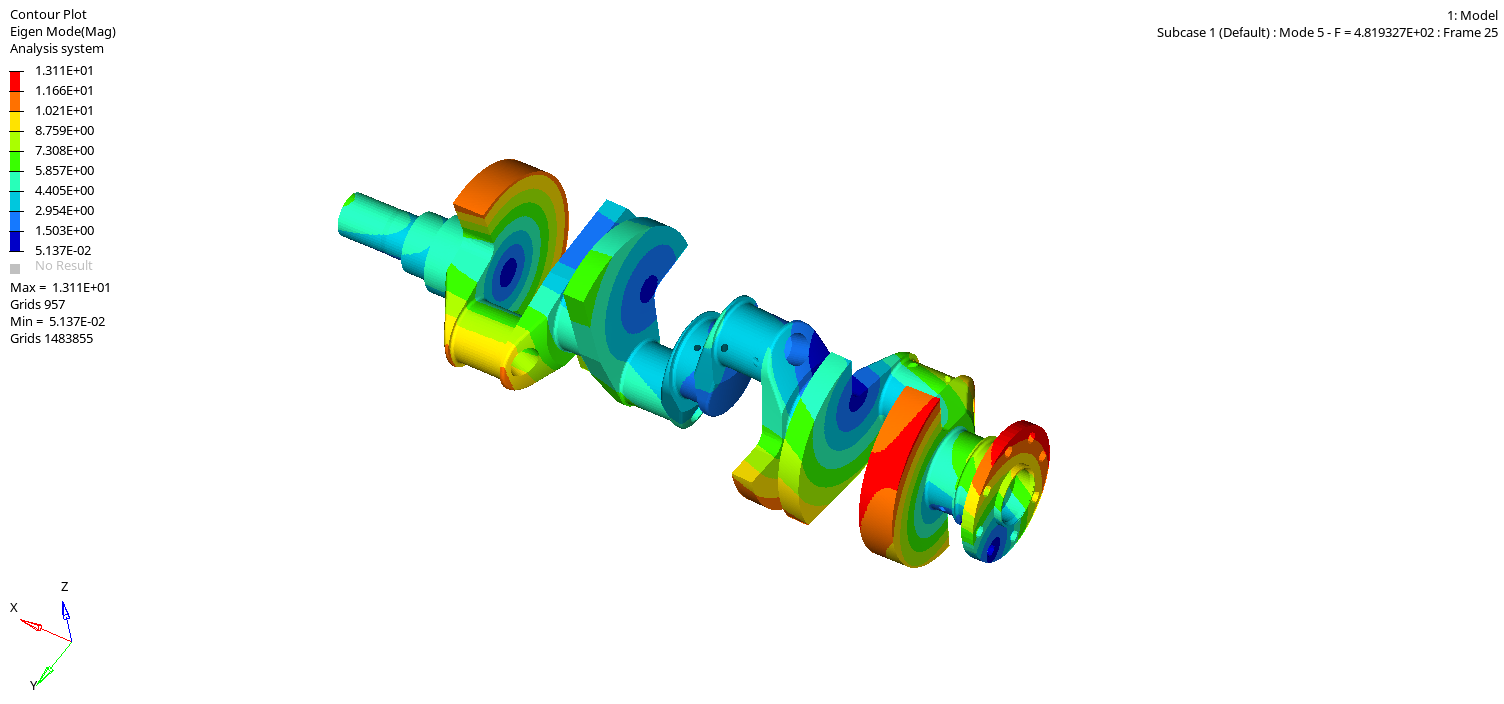

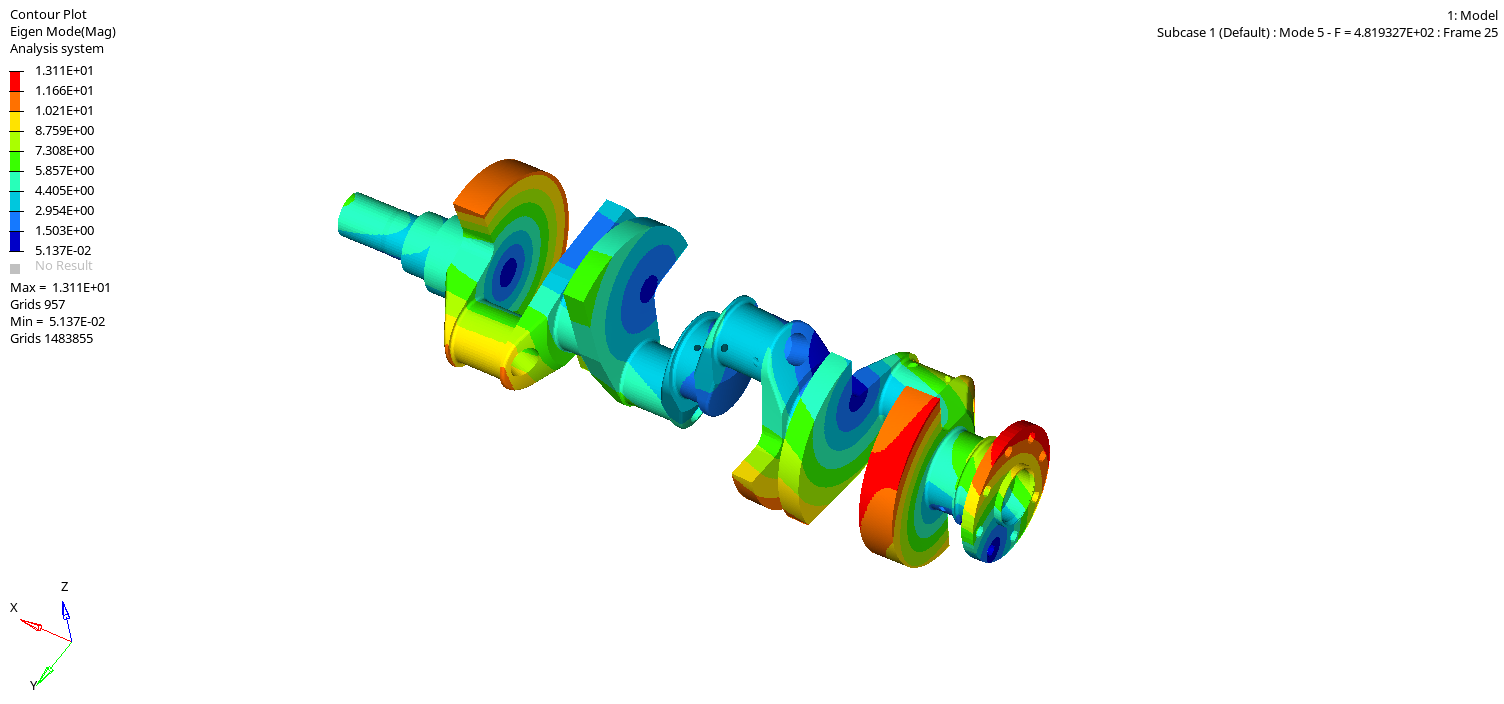

My goal is to have a reasonably accurate CAD model so I can do a bunch of modals on it to understand what rpm the crank shouldn't be run. By reasonably accurate, I mean it will have the right physics but not be perfect enough to to send to CAM and make a crank. (It could be but there is minimal data I can find on the interwebs to place mains 1 and 5 perfectly and to mimic the angles of the cuts on the pork chops.)

Free-free modals are already done. Now I need to CAD up an ATI balancer and create a physically correct TC (inertia-wise) and simulate the mains and finish the analysis stuff. That will drop the torsional mode shown by a bit, I just need to know by how much as it's right at a shift point currently.

Re: Mopar RB Crank Journal Spacing

Posted: Wed Nov 20, 2019 10:07 pm

by SchmidtMotorWorks

Rick! wrote: ↑Tue Nov 19, 2019 7:41 am

My goal is to have a reasonably accurate CAD model so I can do a bunch of modals on it to understand what rpm the crank shouldn't be run. By reasonably accurate, I mean it will have the right physics but not be perfect enough to to send to CAM and make a crank. (It could be but there is minimal data I can find on the interwebs to place mains 1 and 5 perfectly and to mimic the angles of the cuts on the pork chops.)

Free-free modals are already done. Now I need to CAD up an ATI balancer and create a physically correct TC (inertia-wise) and simulate the mains and finish the analysis stuff. That will drop the torsional mode shown by a bit, I just need to know by how much as it's right at a shift point currently.

Are you also including the attached objects?

Are you hoping to optimize angles of the CWs through modal analysis?

Re: Mopar RB Crank Journal Spacing

Posted: Wed Nov 20, 2019 10:42 pm

by Jeff Lee

I always just go kinda high on the RPM then fix the broken parts and back off a few hundred RPM’s...LOL