Tuner,

I read your comments about the Re: Rochester 2bbrl circle track

Post by Tuner » Mon Dec 23, 2019 6:20 pm.

You mentioned "You need the stock three-sided sheet metal baffle around the N&S that is retained by the lid gasket and you might add a baffle to separate the accelerator pump area from the main part of the bowl. There are ridges in the casting to retain a baffle you make with thin piece of brass sheet so it fits from the bottom to the top of the bowl. Cut a little nip off the lower corner toward the front of the bowl to let some fuel get to the pump." . The stock three-sided sheet metal baffle is item 15? in the attached diagram? Could you give me more

info. on the brass sheet baffle that you talk about. A drawing, or how it goes in the bowl area? I have a fuel slosh problem on my motor that, maybe a baffle may fix? Thanks for the help!

Rochester 2bbrl circle track

Moderator: Team

Re: Rochester 2bbrl circle track

You do not have the required permissions to view the files attached to this post.

Re: Rochester 2bbrl circle track

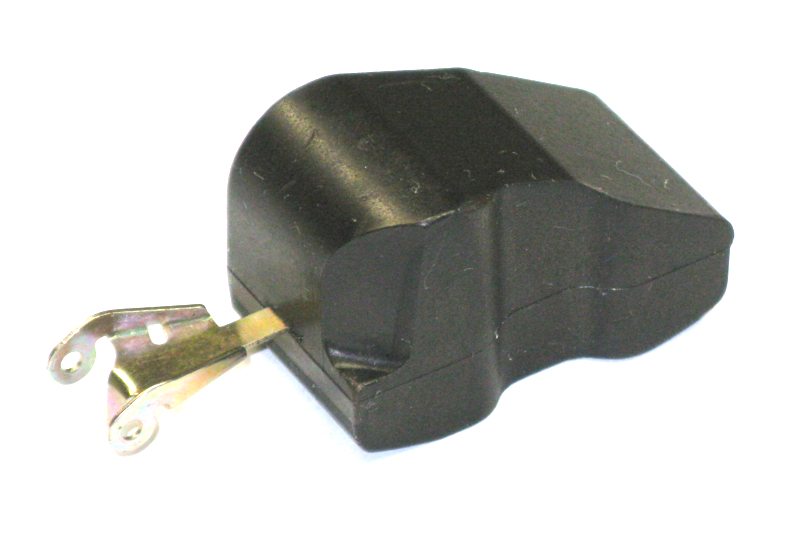

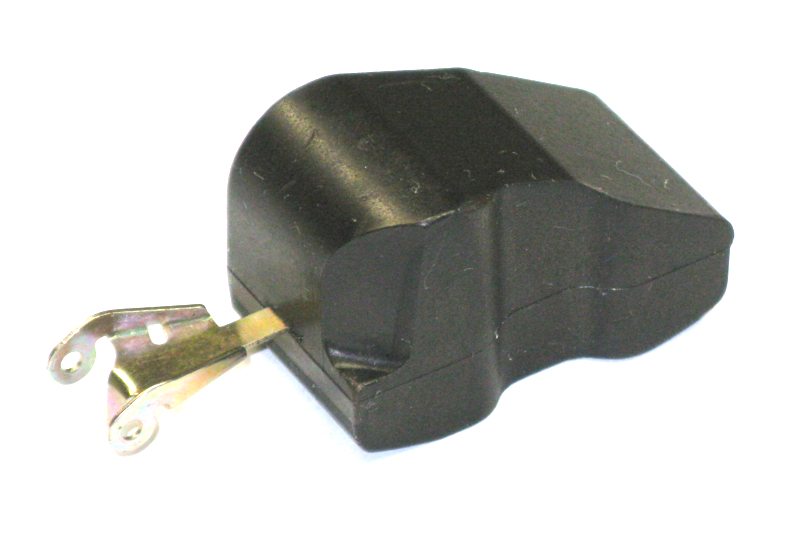

#15 is the baffle around the inlet. It prevents the inrush of fuel which spews from the windows in the side of the seat from hitting the float and interfering with it. I have made a few of thin brass sheet when I didn't have one handy.

Some 2G carbs use a inlet seat that has no windows, like some QJet inlets. Some have different size thread on the inlet seat and will use a QJet inlet, but that requires a little blacksmithing to qualify the length of the needle as I recall (maybe not, haven't done one in several years), no matter the seat can be drilled .136" ~ 140" or whatever is necessary to supply enough fuel.

The flat sheet goes right next to the accelerator pump cylinder, at the opposite end (the throttle side) of the bowl from the inlet and float hinge (choke side). In your good picture you see the square edged ridges on the vertical front and rear sides of the bowl which will retain the sheet against the pump cylinder if sheet is made to the proper size so it has just a slight interference fit. Make it so it is retained by the ridges on front and rear and touching the bottom of the bowl and the gasket at the top. Cut a bit off the the bottom corner toward the front of the car so fuel can get into the area around the pump cylinder to refill the pump when the car is decelerating. My local hardware store has brass sheet in a few different thicknesses. It may be identified as "shim stock" or just brass sheet. You could make the piece out of an old soup can. To get the hang of fitting it, make the first one out of a piece of cardboard (carb kit box, etc.) to use for a template. Scissors will cut the brass sheet.

Metering Clusters: The venturi minor diameter in the 1-3/16" body casting is located higher than in the 1-3/8" body and the booster is shorter to match. Some of the "custom" carb builders use the metering cluster which is used in the 1-3/16" body in the 1-3/8" venturi body because 1-3/16" cluster has shorter boosters which locate the bottom end of the booster higher, up above the minor diameter of the 1-3/8" venturi. The shorter booster makes a bigger air flow number on a flow bench and so with the right jet size may give a bigger max HP number on a dyno, but on the track I think the long booster that exits below the venturi in the correct location to be in the "vena contracta" gives better performance over the whole RPM range. A "custom" 2G with the short boosters needs different size jets to get off the corner best and also pull hardest at the end of the straight.

https://en.wikipedia.org/wiki/Vena_contracta

All carbs, Rochester, Holley and Edelbrock, with the raised or short booster deal need different jet sizes to run well over the whole range of throttle opening and RPM. A single jet size will not satisfy an engine's A/F requirements over the entire air flow range when the booster exit is above the vena contracta. This was figured out 100 years ago. Web search "NACA TR-49" , it was released in 1919.

You need to run the tapered Nitrophil float. Set parallel with the inverted lid.

Some 2G carbs use a inlet seat that has no windows, like some QJet inlets. Some have different size thread on the inlet seat and will use a QJet inlet, but that requires a little blacksmithing to qualify the length of the needle as I recall (maybe not, haven't done one in several years), no matter the seat can be drilled .136" ~ 140" or whatever is necessary to supply enough fuel.

The flat sheet goes right next to the accelerator pump cylinder, at the opposite end (the throttle side) of the bowl from the inlet and float hinge (choke side). In your good picture you see the square edged ridges on the vertical front and rear sides of the bowl which will retain the sheet against the pump cylinder if sheet is made to the proper size so it has just a slight interference fit. Make it so it is retained by the ridges on front and rear and touching the bottom of the bowl and the gasket at the top. Cut a bit off the the bottom corner toward the front of the car so fuel can get into the area around the pump cylinder to refill the pump when the car is decelerating. My local hardware store has brass sheet in a few different thicknesses. It may be identified as "shim stock" or just brass sheet. You could make the piece out of an old soup can. To get the hang of fitting it, make the first one out of a piece of cardboard (carb kit box, etc.) to use for a template. Scissors will cut the brass sheet.

Metering Clusters: The venturi minor diameter in the 1-3/16" body casting is located higher than in the 1-3/8" body and the booster is shorter to match. Some of the "custom" carb builders use the metering cluster which is used in the 1-3/16" body in the 1-3/8" venturi body because 1-3/16" cluster has shorter boosters which locate the bottom end of the booster higher, up above the minor diameter of the 1-3/8" venturi. The shorter booster makes a bigger air flow number on a flow bench and so with the right jet size may give a bigger max HP number on a dyno, but on the track I think the long booster that exits below the venturi in the correct location to be in the "vena contracta" gives better performance over the whole RPM range. A "custom" 2G with the short boosters needs different size jets to get off the corner best and also pull hardest at the end of the straight.

https://en.wikipedia.org/wiki/Vena_contracta

All carbs, Rochester, Holley and Edelbrock, with the raised or short booster deal need different jet sizes to run well over the whole range of throttle opening and RPM. A single jet size will not satisfy an engine's A/F requirements over the entire air flow range when the booster exit is above the vena contracta. This was figured out 100 years ago. Web search "NACA TR-49" , it was released in 1919.

You need to run the tapered Nitrophil float. Set parallel with the inverted lid.

Re: Rochester 2bbrl circle track

I only build e85 fueled 2gv carbs if you are interested they have been top of Usra national points for many years contact me if you are interested

Re: Rochester 2bbrl circle track

I gave the wrong pictures for the cluster assembly shown with the box earlier.

Here is the correct pictures for that box.

Here is the correct pictures for that box.

You do not have the required permissions to view the files attached to this post.

I can do almost anything, just not everything...

Re: Rochester 2bbrl circle track

The 7029215 is found in parts sheets for

1956 Chevrolet 265 V8 Powerglide Carb # 7008388 (std. carb) 7009910 (std. replacement carb no.)

and

1957 Chevrolet 283 V8 Powerglide Carb # 7010648 (early) 7011224 (late)

Re: Rochester 2bbrl circle track

Tuner,

Thanks for explaining the purpose of the No. 15 baffle, and how to make & position the brass baffle in the bowl of the carbs.

Appreciate the help,

Axle32

Thanks for explaining the purpose of the No. 15 baffle, and how to make & position the brass baffle in the bowl of the carbs.

Appreciate the help,

Axle32

Re: Rochester 2bbrl circle track

Tuner, do you have a preference for any of the different boosters for a street car or is it something you will only see a difference with a max effort situation?

Thanks

-

melowisdom

- New Member

- Posts: 1

- Joined: Thu Jan 23, 2020 11:09 pm

- Location: Iowa

Re: Rochester 2bbrl circle track

Guys,

There is a lot of work that needs done to a Rochester 2bbl in order to make it run fast in the dirt circle track world of racing. The tracks I raced on have a 1 3/8 venturi rule and 1/4 inch rule on the cluster venturi or what some call boosters. The very best carb to build these race carbs out of is the 71 through 80 "Truck Booster" 2bbl Rochester. They are getting rarer and rarer by the year to find.

This carb is 1 3/8 venturi, like most that are the 1 3/8 are just under that measurement and there is a casting line that needs to be taken out. By the way, the float bowl is bigger than most of these 2g, 2gc or 2gv carbs. They have a bigger power valve, which the power valve piston spring needs to be modified for low vacuum race cams, this is so the boosters do not drip. The boosters in these carbs are already 1/4 inch and meets the IMCA rules. Like most of these 2g's the cluster needs to be modified in order to get more fuel to the engine. Bigger holes in the air bleeds and emulsion tubes, start out small and watch the fuel curve on a dyno. Bigger is not always better, you can make them too big, then you have wasted a rare cluster. The smaller 2g cluster not only needs bigger holes in the emulsion tubes, it also needs new holes drilled in the top of the cluster housing to move the air bleed from the side and the side air bleeds need plugged. These are very small holes and requires precision drill bits of the best quality, because if you break it off, you may be looking for a new cluster. These holes also need the be in precise places. They are the air bleeds for the emulsion tubes.

A .130 needle and seat needs to be added to most of these carbs. You can drill out a stock one but do it very slowly with fine drill bits and clean up any burs inside and out. You do not need the deflection box around the needle and seat. Use a replacement small area brass float. Also, two holes need to be drilled in the butterflies one in each, in the middle just below the throttle shaft on the fuel mixture hole side of the butterfly as it sits in the carb. Start small. These holes allow for good crisp starts an restarts.

It is very easy to make a great Rochester 2bbl out of the 1 1/4 venturi, but takes a lot of work removing material. You can do it with a Dremel with the right metal removing bits, inside calipers and lots of patients, because you do not want to go over 1.375. I take them to 1.36 and sand them the rest of the way to 1.37 and no further to get 500 to 510 CFM with the other modifications mentioned.

Hope this helps, TJ

There is a lot of work that needs done to a Rochester 2bbl in order to make it run fast in the dirt circle track world of racing. The tracks I raced on have a 1 3/8 venturi rule and 1/4 inch rule on the cluster venturi or what some call boosters. The very best carb to build these race carbs out of is the 71 through 80 "Truck Booster" 2bbl Rochester. They are getting rarer and rarer by the year to find.

This carb is 1 3/8 venturi, like most that are the 1 3/8 are just under that measurement and there is a casting line that needs to be taken out. By the way, the float bowl is bigger than most of these 2g, 2gc or 2gv carbs. They have a bigger power valve, which the power valve piston spring needs to be modified for low vacuum race cams, this is so the boosters do not drip. The boosters in these carbs are already 1/4 inch and meets the IMCA rules. Like most of these 2g's the cluster needs to be modified in order to get more fuel to the engine. Bigger holes in the air bleeds and emulsion tubes, start out small and watch the fuel curve on a dyno. Bigger is not always better, you can make them too big, then you have wasted a rare cluster. The smaller 2g cluster not only needs bigger holes in the emulsion tubes, it also needs new holes drilled in the top of the cluster housing to move the air bleed from the side and the side air bleeds need plugged. These are very small holes and requires precision drill bits of the best quality, because if you break it off, you may be looking for a new cluster. These holes also need the be in precise places. They are the air bleeds for the emulsion tubes.

A .130 needle and seat needs to be added to most of these carbs. You can drill out a stock one but do it very slowly with fine drill bits and clean up any burs inside and out. You do not need the deflection box around the needle and seat. Use a replacement small area brass float. Also, two holes need to be drilled in the butterflies one in each, in the middle just below the throttle shaft on the fuel mixture hole side of the butterfly as it sits in the carb. Start small. These holes allow for good crisp starts an restarts.

It is very easy to make a great Rochester 2bbl out of the 1 1/4 venturi, but takes a lot of work removing material. You can do it with a Dremel with the right metal removing bits, inside calipers and lots of patients, because you do not want to go over 1.375. I take them to 1.36 and sand them the rest of the way to 1.37 and no further to get 500 to 510 CFM with the other modifications mentioned.

Hope this helps, TJ