Thanks for all the support.

I'll try an cover everyone's questions.

Everyone is correct about coating over existing coatings. I did some calling on the coating issue and talked to quite a few places. But did not find exactly what I was looking for, and this was from watching the coating trend on the Nascar stuff, that I use for a reference, I figure I should be able to benefit from all the money they spend on R&D.

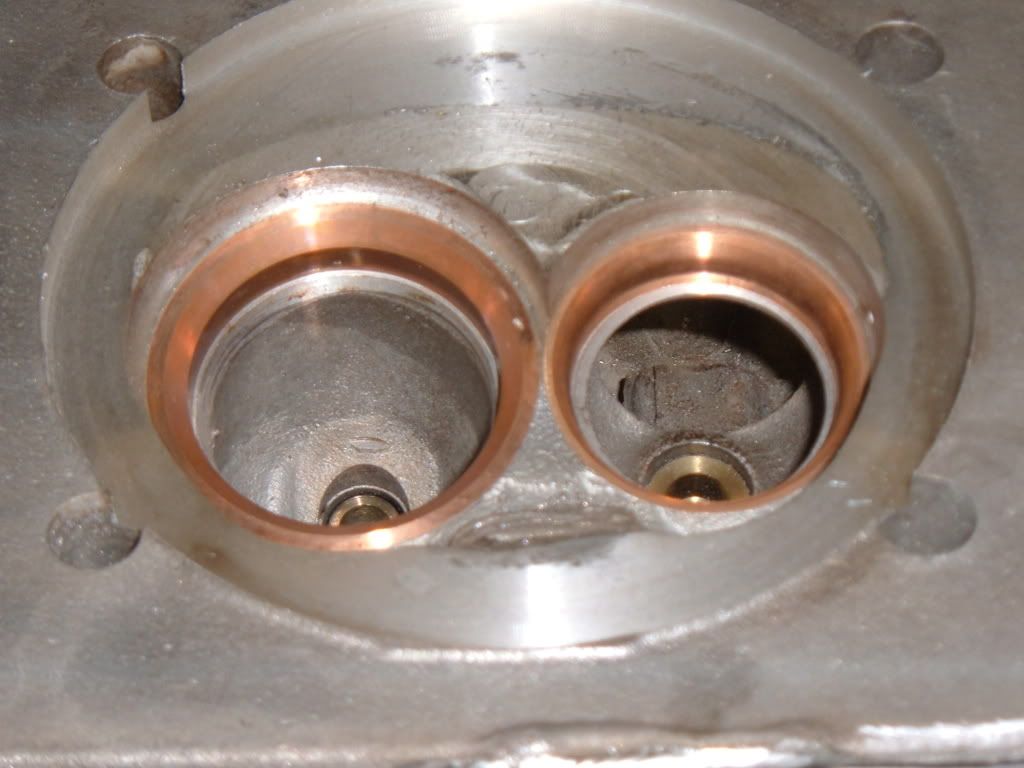

I did find a place that will do the coatings. The Int valve stems & faces were Casidium coated, but the coating on the valve face & tip was cut away.

The original stem length was around 5.900" and was cut to just under 5.0", and the faces were cut from 2.180" to 1.9" on the Int, the exh, just the stems were cut, the heads stayed at 1.580".

All that will be coated are just the freshly machined surfaces, valve seat face's, the keeper groves & tips, the rest will be masked off. The coating will be a DLC, the exh coating will be slightly different than the Int, to be able to handle the Exh temps. The company:

http://www.richterprecision.com/

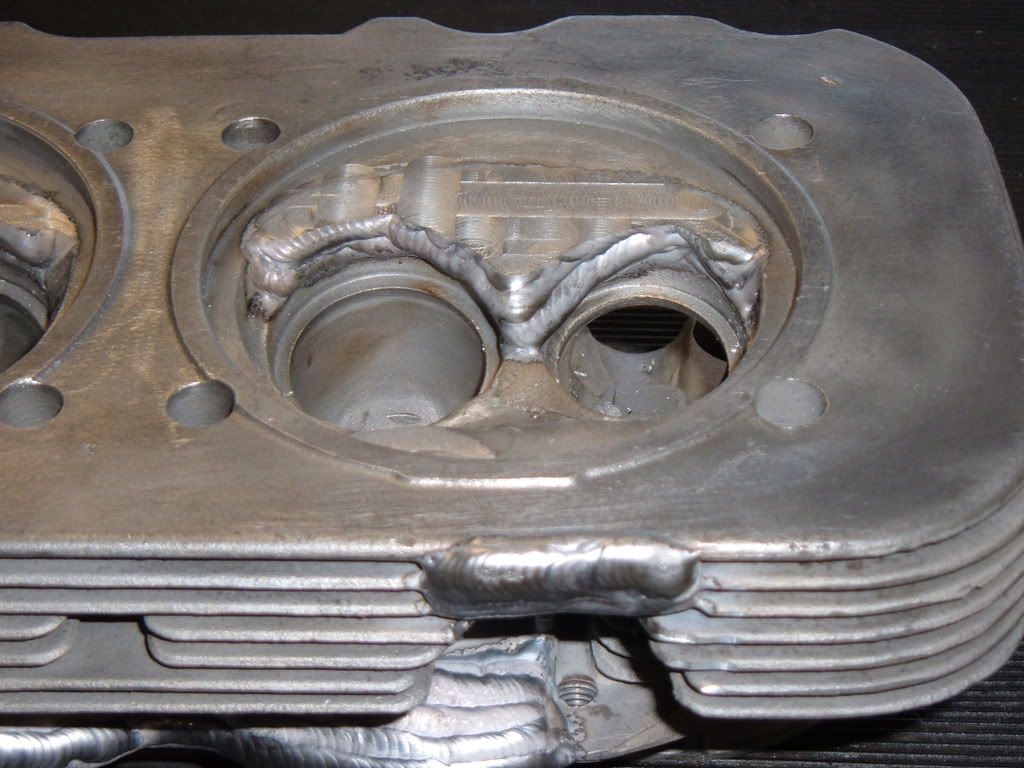

The machine work, I can do some minor stuff, but the valves, seats & guides are beyond my current ability, so I didn't do those.

As for the guides, the Int's are not pressed all the way in yet, and were only partially installed for room for port work and a guide to install the seats. The Exh have another issue, the valves were designed for a SB2 head and the distance from the taper on the stem to the guide was not an issue, but on my app the taper runs into the guide because the ports are so short, and the port and guide have been cut as much as possible, so now I will have to drill a clearance hole in the guide for the stem taper clearance. I knew this ahead of time from mock ups and was thinking at first just to get some SS 7mm stemmed blanks, but they would of been heavier, and this whole thing was about getting everything as lite as possible.

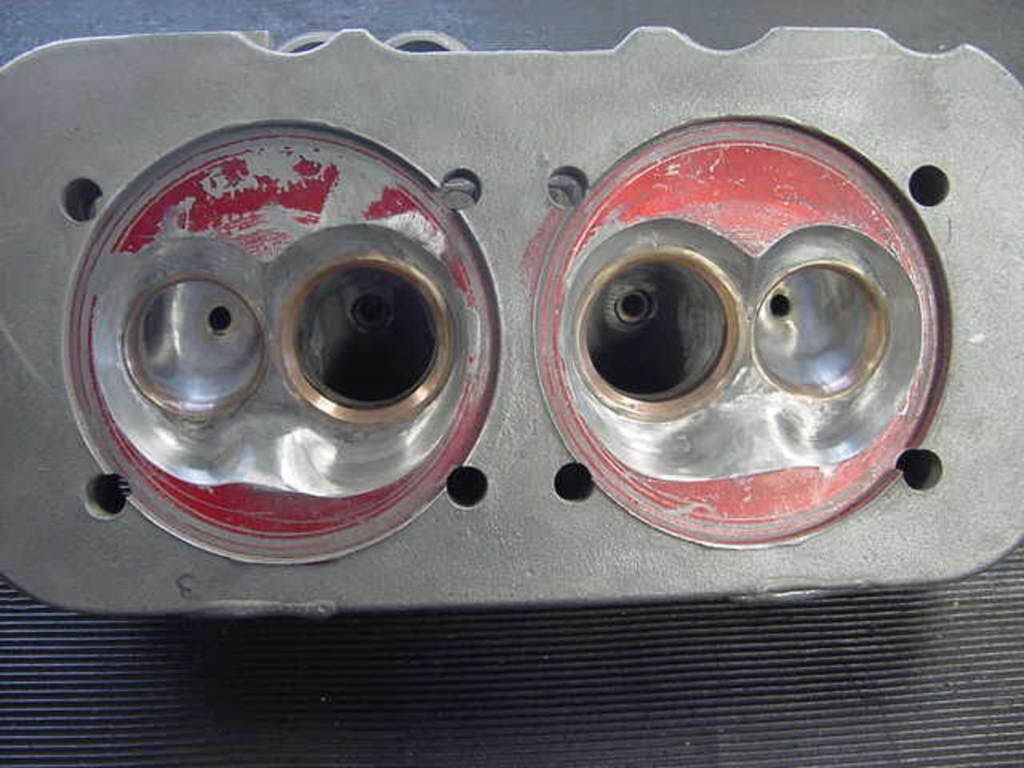

I know I am pushing the limits on this, but only to a point, I will be running about a third of the spring pressure that these would normally be ran at, and with the shorter stems they should have less leverage than a longer stem would and hopefully less wear.

I am waiting on some machine work, then finish the porting, then they go out to get the seats cut, then cc the chambers, then I will have one chamber flowed.