Second compression ring iron ?

Moderator: Team

-

Little Mouse

- Expert

- Posts: 859

- Joined: Mon Oct 21, 2013 8:48 pm

- Location:

Second compression ring iron ?

In ring sets the top ring is ductile iron, second ring is regular iron. Why is the second ring not same type of iron. I know the top ring gets all the heat but what's wrong with making the second ring out of same ductile iron.

-

engineguyBill

- Guru

- Posts: 1264

- Joined: Fri Feb 26, 2010 11:15 am

- Location: Gold Canyon, AZ

Re: Second compression ring iron ?

Some ring manufacturers do offer second rings in ductile iron or steel, but these materials are over-kill for this ring.

The second ring is described by ring manufacturers as a dual-purpose ring (80% oil control; 20% combustion pressure control) and grey iron works very well for this function. As you stated the second ring does not encounter high levels combustion heat/pressure and being an oil scraper, it is bathed in oil therefore heat and friction are not important environments for this ring.

The second ring is described by ring manufacturers as a dual-purpose ring (80% oil control; 20% combustion pressure control) and grey iron works very well for this function. As you stated the second ring does not encounter high levels combustion heat/pressure and being an oil scraper, it is bathed in oil therefore heat and friction are not important environments for this ring.

Bill

Perfect Circle Doctor of Motors certification

SAE Member (30 years)

ASE Master Certified Engine Machinist (+ two otherASE Master Certifications)

AERA Certified Professional Engine Machinist

Perfect Circle Doctor of Motors certification

SAE Member (30 years)

ASE Master Certified Engine Machinist (+ two otherASE Master Certifications)

AERA Certified Professional Engine Machinist

Re: Second compression ring iron ?

TOP

OE 96-up iron Vortec, LS1, LQ4. LQ9 all Steel TOP rings. All thin ringpaks w/ narrow radial wall thickness.

IIRC, steel rings are cheaper to produce IN BULK ... less machining than iron. OE is all about $/production efficiency/fuel efficiency

OE 96-up iron Vortec, LS1, LQ4. LQ9 all Steel TOP rings. All thin ringpaks w/ narrow radial wall thickness.

IIRC, steel rings are cheaper to produce IN BULK ... less machining than iron. OE is all about $/production efficiency/fuel efficiency

Re: Second compression ring iron ?

I don't see how it would work better to make it ductile iron instead of the CORRECT alloy of iron.

If you went to steel the ring could be maybe 10% lighter, but ductile iron....no advantage

If you went to steel the ring could be maybe 10% lighter, but ductile iron....no advantage

Re: Second compression ring iron ?

Just curious...... Had great luck with Grant graphite rings many moons ago. Do not see them in current listings. From memory, I'm assuming these were ductile iron or grey iron 2nd ring with a carbon-graphite top ring? Or perhaps both were carbon-graphite? So far, have only found mention of these type rings for air compressors, etc. Anyone have a source for this type ring (automotive applications)?

Thanks,

Harry

Thanks,

Harry

Re: Second compression ring iron ?

are the ductile iron rings less likely to break when installing lol

-

Little Mouse

- Expert

- Posts: 859

- Joined: Mon Oct 21, 2013 8:48 pm

- Location:

Re: Second compression ring iron ?

Seems like rings along with pistons of course have a rough life, cant see why better quality ductile iron could not be used for the second ring.

-

engineguyBill

- Guru

- Posts: 1264

- Joined: Fri Feb 26, 2010 11:15 am

- Location: Gold Canyon, AZ

Re: Second compression ring iron ?

Ductile iron IS available as an optional second ring from several ring manufacturers, BUT the grey iron used for the majority of second rings holds up just fine in most applications from OEM passenger car to maximum effort race engine applications. If the second ring is failing, there is something seriously wrong with the engine . . . . . . .

Bill

Perfect Circle Doctor of Motors certification

SAE Member (30 years)

ASE Master Certified Engine Machinist (+ two otherASE Master Certifications)

AERA Certified Professional Engine Machinist

Perfect Circle Doctor of Motors certification

SAE Member (30 years)

ASE Master Certified Engine Machinist (+ two otherASE Master Certifications)

AERA Certified Professional Engine Machinist

Re: Second compression ring iron ?

Ring tension is greater when comparing Ductile iron vs grey iron, bad for gas mileage I would imagine.Little Mouse wrote: ↑Sun Mar 01, 2020 10:30 pm Seems like rings along with pistons of course have a rough life, cant see why better quality ductile iron could not be used for the second ring.

Re: Second compression ring iron ?

Thanks, modok. I have gone through their catalogue on several occasions over the past several years. Seems the graphite rings have not been continued. I have contacted them, but the people there now know only the current product line.

Dad knew Mr. Grant. I have a photo of them sitting next to one another at a piston ring convention. Its dated 1928 on the back. That was around the time Dad married Mom and they started up their automotive machine shop in Little Rock. They did that until just after WWII when Dad's health began to fail. He passed in 1951. Rolled a '39 Chevy on his way back from the VA hospital. Bumper jack stowed behind the seat hit him in the temple. Otherwise he might have made it.

When I built my first engine as a kid in 1963, Mom insisted that I use Grant graphite piston rings, Federal Mogul bearings and Victor gaskets. By that time Mom had remarried and the machine shop in Arkansas was just a memory. The DeSoto hemi I built was done under a pole barn backed up to an alfalfa field in the Texas hill country. Ran the heck out of that engine and gave the '55 Ford it was in to my Step-dad when I left for the service in June of '66. Whilst I was away, he pulled it out and put a Y-block Ford engine back in it and drove it as a work car. When I returned, I gave the DeSoto engine to the man I had worked for after school and he put it in his Dodge wrecker. Last I heard (1978), the DeSoto was still running well.

That's why I'd love to have a set of graphite rings for this last engine build. I ran the hell out of that DeSoto engine for 3 years as only a teenager can and it was one of the best running engines I've ever built. The Grant graphite rings sealed quickly whilst breaking in the engine and from then on in, it was run flat out every chance I got. A buddy and I were running side by side on I-35 driving back home from the drag strip in San Antonio a few weeks before I left for boot camp. Speedometers in both cars were long since buried but John had a tach in his '57 Chevy and we calculated based on RPMs that we were running 138 MPH when the rear window got sucked out of my hemi powered Ford. Now I know why the NASCAR guys used to screw those metal strips over their rear windows.

I'll see if I can find any NOS Grant graphite rings from vintage parts dealers. The inline 6 I am working on has same standard bore size as a 283 Chevy V-8.

Best regards,

Harry

Re: Second compression ring iron ?

I don't know what the "graphite" was all about, maybe a catchy name for the iron alloy or a surface treatment they were using.

Very fancy name for cast iron if I ever heard one.

Did you know cast iron is actually a "composite material" composed of iron and graphite?

Tho I think they DO have a darn good handle on, the right alloy of iron. Break in fast, lasts long.

But there is a HECK of a lot more kinds of iron than two. if it is or isn't ductile has almost zero to do with the hardness or wearing properties of it.

Very fancy name for cast iron if I ever heard one.

Did you know cast iron is actually a "composite material" composed of iron and graphite?

Tho I think they DO have a darn good handle on, the right alloy of iron. Break in fast, lasts long.

But there is a HECK of a lot more kinds of iron than two. if it is or isn't ductile has almost zero to do with the hardness or wearing properties of it.

Re: Second compression ring iron ?

Modok, from what I recall, the Grant rings were a cast iron ring having a goodly amount of graphite in the metal. I don't believe it was a coating. Seemed more like the graphite was impregnated into the base metal by some process during manufacture.

This was a 'few' years ago. 1963. I was 15. I am 72 now. My first engine build. I didn't have any proper tools except for a few wrenches, sockets and a breaker bar. No piston hone, no torque wrench, no piston ring spreader. After cutting out the ridge, I 'honed' the cylinders and polished the crankshaft by hand using croatner's cloth soaked in kerosene and plenty elbow grease. Hand lapped the valves using Clover Leaf lapping compound and a suction cup with a wooden handle.

This was before we moved into town (San Marcos). We were still in the old farm house a piece down the road down the road from Geronimo, which was on he old road from San Marcos to Seguin. No running water and no electric, so no way to run a hone even if I'd had one. Had to spread and install each ring by hand, being careful not to break them and not to gouge the piston surface as I slipped them over the pistons and down into the ring grooves.

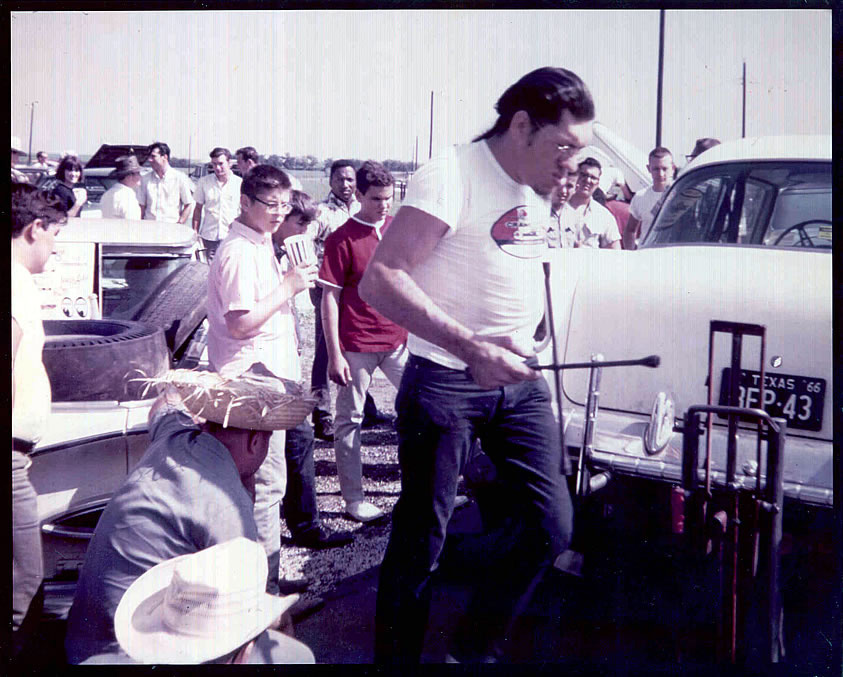

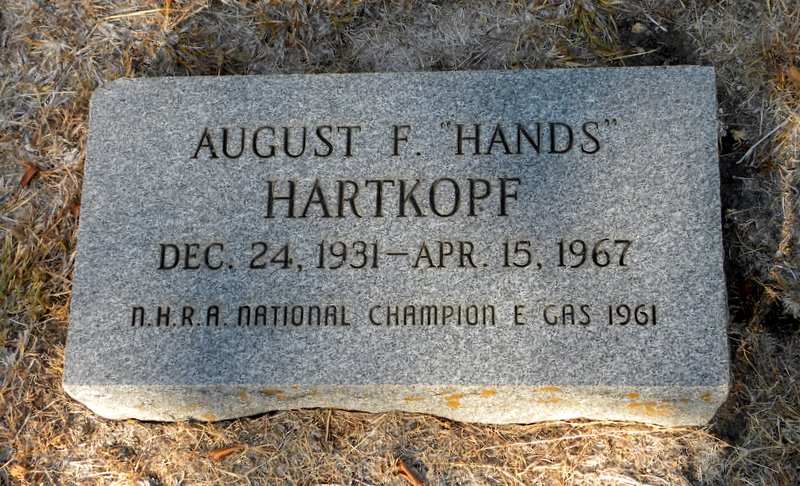

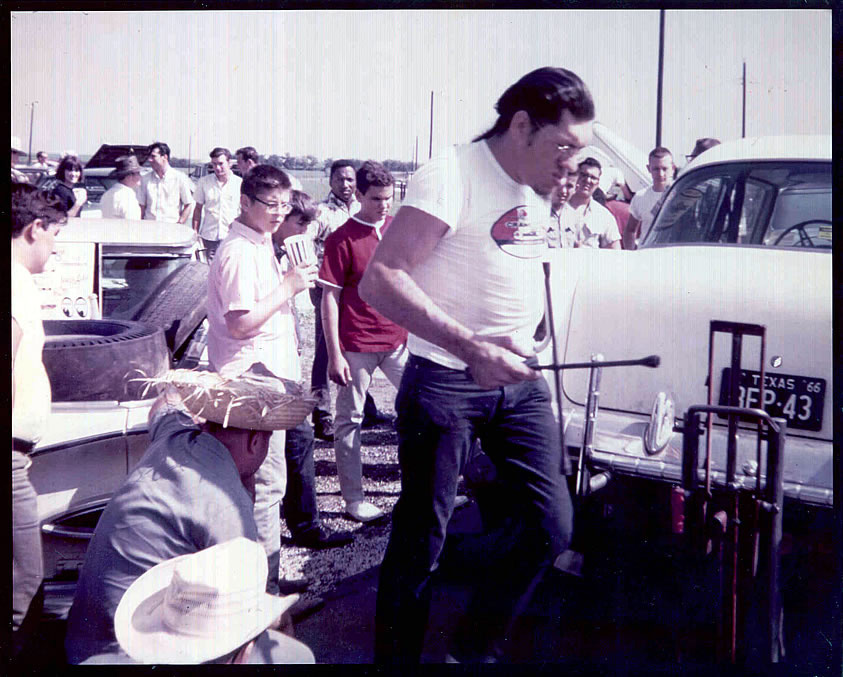

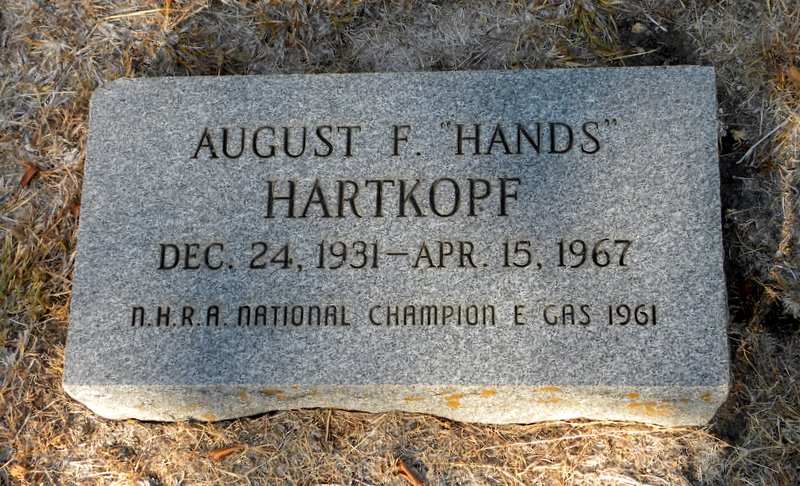

My friend John and his older brother knew Auggie Hartkoph up in Austin and John borrowed a ring compressor from him for me when I was putting the DeSoto engine back together. Auggie was the only guy I've met who had larger hands and feet than me. Huge guy. I reckon he must have been way over 7 ft. tall. Auggie raced a '56 Chevy and a '55 Chevy and had a roadster as well. I remember he ran a Crane cam in his '55 and Schneider cams in his '56 and the roadster.

We had gone down to the drag strip in San Antonio to watch Auggie run the day John and I decided to open up our cars out on I-35 on the way back and see just how fast they would run flat out in 1966. That was when the rear window got sucked out of my '55 Ford.

Auggie's hands would span the steering wheel in his Chevy. That's why his nickname was 'Hands'. I found this photo of Auggie online. The '59 El Camino with the slicks in the back was Auggie's tow car. My friend John is at the extreme left. John was 6'-1" tall so that should give you some idea how big Auggie was.....

Sadly, I never saw Auggie again. He passed away whilst I was in Nam. He was one of those larger than life guys you never forget.

Best regards,

Harry

This was a 'few' years ago. 1963. I was 15. I am 72 now. My first engine build. I didn't have any proper tools except for a few wrenches, sockets and a breaker bar. No piston hone, no torque wrench, no piston ring spreader. After cutting out the ridge, I 'honed' the cylinders and polished the crankshaft by hand using croatner's cloth soaked in kerosene and plenty elbow grease. Hand lapped the valves using Clover Leaf lapping compound and a suction cup with a wooden handle.

This was before we moved into town (San Marcos). We were still in the old farm house a piece down the road down the road from Geronimo, which was on he old road from San Marcos to Seguin. No running water and no electric, so no way to run a hone even if I'd had one. Had to spread and install each ring by hand, being careful not to break them and not to gouge the piston surface as I slipped them over the pistons and down into the ring grooves.

My friend John and his older brother knew Auggie Hartkoph up in Austin and John borrowed a ring compressor from him for me when I was putting the DeSoto engine back together. Auggie was the only guy I've met who had larger hands and feet than me. Huge guy. I reckon he must have been way over 7 ft. tall. Auggie raced a '56 Chevy and a '55 Chevy and had a roadster as well. I remember he ran a Crane cam in his '55 and Schneider cams in his '56 and the roadster.

We had gone down to the drag strip in San Antonio to watch Auggie run the day John and I decided to open up our cars out on I-35 on the way back and see just how fast they would run flat out in 1966. That was when the rear window got sucked out of my '55 Ford.

Auggie's hands would span the steering wheel in his Chevy. That's why his nickname was 'Hands'. I found this photo of Auggie online. The '59 El Camino with the slicks in the back was Auggie's tow car. My friend John is at the extreme left. John was 6'-1" tall so that should give you some idea how big Auggie was.....

Sadly, I never saw Auggie again. He passed away whilst I was in Nam. He was one of those larger than life guys you never forget.

Best regards,

Harry

-

engineguyBill

- Guru

- Posts: 1264

- Joined: Fri Feb 26, 2010 11:15 am

- Location: Gold Canyon, AZ

Re: Second compression ring iron ?

Wow, I remember seeing Auggie racing his '55 Chevy at AHRA races in Phoenix at the old Beeline Dragstrip in the mid 60's. His hands were huge and he was very distinctive looking with wire-rim glasses and long hair, tied into a pony tail long before that was in vogue for us guys. His cars were awesome fast and as I recall he ran in B/Gas or C/Gas, probably 301" high-winding SBC with Hilborn fuel injection.

Bill

Perfect Circle Doctor of Motors certification

SAE Member (30 years)

ASE Master Certified Engine Machinist (+ two otherASE Master Certifications)

AERA Certified Professional Engine Machinist

Perfect Circle Doctor of Motors certification

SAE Member (30 years)

ASE Master Certified Engine Machinist (+ two otherASE Master Certifications)

AERA Certified Professional Engine Machinist

-

engineguyBill

- Guru

- Posts: 1264

- Joined: Fri Feb 26, 2010 11:15 am

- Location: Gold Canyon, AZ

Re: Second compression ring iron ?

Most piston ring manufacturers do coat their Ductile iron and cast iron compression rings with Molybdenum after all machining processes are completed. This coating is mainly applied to help keep the iron rings from getting rusty before installation. In the case of Grant Rings, they probably used some combination of Graphite and Moly as a coating for their product. Am pretty certain that all Grant rings back in the day were grey cast iron, not Ductile.modok wrote: ↑Mon Mar 02, 2020 3:10 am I don't know what the "graphite" was all about, maybe a catchy name for the iron alloy or a surface treatment they were using.

Very fancy name for cast iron if I ever heard one.

Did you know cast iron is actually a "composite material" composed of iron and graphite?

Tho I think they DO have a darn good handle on, the right alloy of iron. Break in fast, lasts long.

But there is a HECK of a lot more kinds of iron than two. if it is or isn't ductile has almost zero to do with the hardness or wearing properties of it.

Bill

Perfect Circle Doctor of Motors certification

SAE Member (30 years)

ASE Master Certified Engine Machinist (+ two otherASE Master Certifications)

AERA Certified Professional Engine Machinist

Perfect Circle Doctor of Motors certification

SAE Member (30 years)

ASE Master Certified Engine Machinist (+ two otherASE Master Certifications)

AERA Certified Professional Engine Machinist