Most engines have a valve stem protrusion height tolerance, usually gauged off the spring seat and increasingly important if you have a non-adjustable hydraulic valvetrainWhy are the valve tips important? Is that specifically for this engine because of Valvetronic? I was thinking that valve height could be an issue because of that Valvetronic but then again the hydraulic lifters should even things out if the valve height is within the spec

On older V8s this can be up to 40 thou,or so, but in your case I’m guessing it’s not so generous

Ideally you need to obtain this tolerance ….. maybe an AERA member can help ….. but if you can’t the one way would be to adopt an empirical approach to it

If so assemble your least worn valve / seat combo, assess the ‘wear’ as best you can, measure the stem protrusion and deduct this, minus about another ten thou or so

This you’d consider your minimum stem protrusion height, and your tolerance above this in length would what would seem reasonable ….. 10 thou or so would not seem unreasonable

You should have a 20 thou or so tolerance over what previously ran

The big problem you’ll now have is correcting all 32 valve heights …… although with your new exhausts you will probably be able to juggle a few to get them in spec …… most machinists just won’t want to know, as the last person to touch it is always the first to blame when something goes wrong

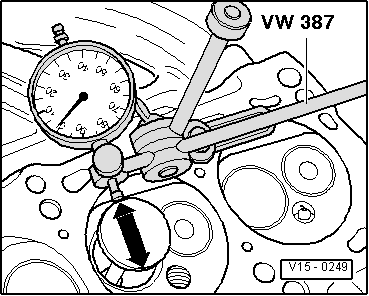

So you need to ‘jerryrig’ something to tip the stems to something approaching perpendicular ….. it’s not as difficult as it sounds in all honesty

To help set the heights turn up a tube that equates your maximum stem protrusion tolerance as your metric, and use a vernier to measure and adjust

Just be wary of taking too much off any one valve tip and run into retainer clearance problems

For what you’re doing, you don’t really need one, just compress a pair of springs in series and gauge each, selecting one as a control to check the rest ….. any duds will be obviousValve spring tester, no I dont have that neither

As regards the rest of it, it’s a shame you bought the Neways, you’d have been better off with any reasonable ball bearing stoneholder stone set up, but you have what you have

IIRC the Neways run interference angles, 46deg etc

I’d put all you angles in with the cutters, and either get the guy who skims ‘em to kiss just the seats with a stone or look online for a cheap used set up …… or even just a couple of pilots and stones, stoneholder & dresser

Lap everything in with 600 grit or finer

Also check the valve guide bores in the head casting when you knock them out, shine a light in there and you’ll soon see if you’ve a problem ….. likewise assess each individual fit when they go back in

I’m sure some might drive a coach and horses through all this, but it will get you close if you’re sharp and have an aptitude for it …… and if it all goes pear shaped as you say pick up another pair of heads