I can't recall any HG ever leaking/blowing towards the fastener, and having this on multiple cyls proves the point.

Live with it, replace the block, or some magic stuff on threads - remove'm one at a time - clean inside & out - thread lock, stud mount, whatever, then re-torque.

Forget the waterjacket stuff for now, you've got bigger problems.

Sbc leakdown test reveals leak to ARP studs threads

Moderator: Team

-

allencr267

- Pro

- Posts: 362

- Joined: Wed Nov 07, 2012 6:28 pm

- Location: Tallahassee Florida USofA

-

BillK

- Guru

- Posts: 1756

- Joined: Wed Aug 26, 2009 8:30 pm

- Location: Beautiful Southern Maryland

- Contact:

Re: Sbc leakdown test reveals leak to ARP studs threads

So you are thinking that the pressure is getting past the rings into the crankcase and then how is it getting into the water jacket ?? Unless I am reading his post wrong he is leakdown testing the cylinders, not pressure testing the cooling system.allencr267 wrote: ↑Tue Jun 01, 2021 11:41 am I can't recall any HG ever leaking/blowing towards the fastener, and having this on multiple cyls proves the point.

Live with it, replace the block, or some magic stuff on threads - remove'm one at a time - clean inside & out - thread lock, stud mount, whatever, then re-torque.

Forget the waterjacket stuff for now, you've got bigger problems.

Bill Koustenis

Advanced Automotive Machine

Waldorf Md

www.enginerepairshop.com

Advanced Automotive Machine

Waldorf Md

www.enginerepairshop.com

Re: Sbc leakdown test reveals leak to ARP studs threads

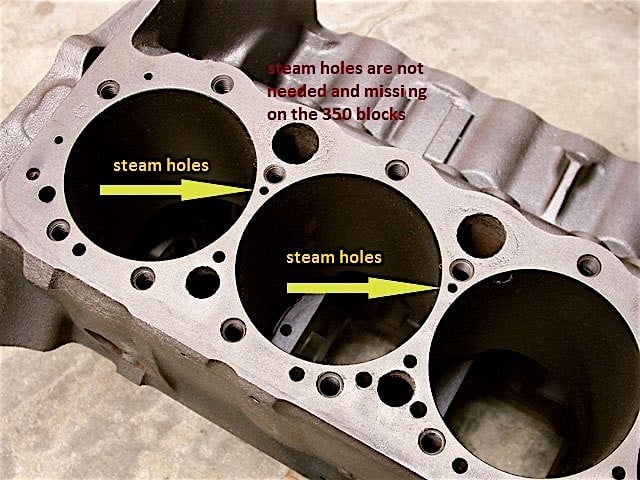

Steam holes could have something to do with this maybe ?Justa1time wrote: ↑Sun May 30, 2021 8:37 pm The block is a GM sportsman 400 block (specific bore size unknown).

Easy with the horror stories that get started because some idiots will use too much "stop leak" (which may or may not contain Sodium Silicate) and when too much is not enough more always better.rebelrouser wrote: ↑Tue Jun 01, 2021 9:45 amOne thing I will point out, when using water glass, READ the directions, no antifreeze in the engine when sealing the leak. I have had customers on stock vehicles try and use water glass and did not read the directions, totally destroyed their radiators and heater cores. When using with antifeeze it makes a kind of jelly. Not good. They told me they drained the radiator, and I said what about the block?bassettmustang86 wrote: ↑Tue Jun 01, 2021 12:55 am Either way the heads need to come off the block needs to be checked. First check the gasket,check block for cracks, and see if the block has blind bolt holes are not.

I have used the pure sodium silicate product you buy in a pint jar from a pharmacy for decades, several decades, and never had a problem with it clogging anything but the leaks.

What people don't understand is how little it takes to stop a little seep that isn't a gaping crack The clue is it doesn't require any more than will fill the gap.

Did you notice my instruction is to use 1/2 teaspoon of AlumaSeal powder with 1 ounce of sodium silicate? That will not clog anything but will solve the OP's problem if it is just water seeping up the threads.

I have used 3-4 ounces in a cooling system that had regular old-school ethylene glycol antifreeze and not seen any jelly form. Maybe the water in your neighborhood is contaminated with minerals or something that causes that .

Re: Sbc leakdown test reveals leak to ARP studs threads

Guys, he's not pressure testing the cooling system and he specifically said that there aren't any bubbles coming up through the radiator cap opening when he performed the leakdown on all of the cylinders, but pressure did come up through the head bolts (studs). That leaves only one possibility, and that's combustion pressure leaking past the head gasket at whatever they're using for a fire ring and going into the head bolt boss in the cylinder head.

It needs to be torn down. If it leaks combustion pressure at 100psi, what do you think is going to happen at 1500psi+ when at full throttle?

I've had radiators damaged by debris on the track before (asphalt circle track) and used various things as temporary repairs. If you don't have alumaseal or bar's leaks handy, egg whites will work as will hot dog buns, believe it or not.

It needs to be torn down. If it leaks combustion pressure at 100psi, what do you think is going to happen at 1500psi+ when at full throttle?

I've had radiators damaged by debris on the track before (asphalt circle track) and used various things as temporary repairs. If you don't have alumaseal or bar's leaks handy, egg whites will work as will hot dog buns, believe it or not.

Re: Sbc leakdown test reveals leak to ARP studs threads

Oops, you're right. He could use a 4 or 5 gas combustion analyzer and sniff the radiator for combustion gasses, or one of these to confirm what you are saying is true. https://www.summitracing.com/parts/lil- ... gJaVPD_BwEdannobee wrote: ↑Tue Jun 01, 2021 4:01 pm Guys, he's not pressure testing the cooling system and he specifically said that there aren't any bubbles coming up through the radiator cap opening when he performed the leakdown on all of the cylinders, but pressure did come up through the head bolts (studs). That leaves only one possibility, and that's combustion pressure leaking past the head gasket at whatever they're using for a fire ring and going into the head bolt boss in the cylinder head.

It needs to be torn down. If it leaks combustion pressure at 100psi, what do you think is going to happen at 1500psi+ when at full throttle?

I've had radiators damaged by debris on the track before (asphalt circle track) and used various things as temporary repairs. If you don't have alumaseal or bar's leaks handy, egg whites will work as will hot dog buns, believe it or not.

-

rustbucket79

- Guru

- Posts: 2151

- Joined: Fri Apr 07, 2006 8:23 pm

- Location:

Re: Sbc leakdown test reveals leak to ARP studs threads

I don’t believe the Sportsman block has steam holes, and I think they have blind head bolt holes. Head gasket failure is a reasonable diagnosis.

-

Justa1time

- HotPass

- Posts: 176

- Joined: Sat Jan 26, 2019 7:22 am

- Location: Redmond, Oregon

Re: Sbc leakdown test reveals leak to ARP studs threads

Good evening everyone,

I really do appreciate all of your replies. I have NOT discovered any pressure from the cylinder leakdown test entering the cooling system of this engine during this test. I do appreciate the insight about the sealing options Tuner and others have mentioned in their replies and I will save those for my memory bank of solutions to future problems I may come across.

The real issue is the pressure from the cylinder is excapaing to its surrounding head studs. There appears to be a real lack of these situations documented online and thats surprising to me. I am not wanting to add a sealant to the threads of the fasteners to curb the issue. The fundamentals of this problem in my perspective is the pressure in the cylinder is somehow leaving the cylinder and leaking into a portion of the engine it does not belong and that is into the head stud provisions machined into the cylinder head casting surrounding the cylinders tested. The pressure does not do me any good there!

Danobee: I am going to have to pull this engine apart and check the surface finishes and also the head gaskets requirements for sealing for sure. I am going to look into better gasket material.

Rustbucket79 and NWHP: I am waiting on an MSD6al box to come back from repair and I will do just that - leakdown test the cylinders while the engine is at operating temp and compare the results with the cold leakdown test.

Bill: I like your idea of marking each fastener and losing half a turn then torturing and studying the relationship between then original nut position to the new.

Momus: Absolutely agree with tearing the engine down but not quite there yet. I want to form a solid plan on what parts I need before the teardown. I must wait for more room in my work area to dissasemble this engine. I have another engine in progress at the moment.

RFOLL: I did call AFR and speak with two different representatives. I sent photographs of the heads and markings to both representatives and neither can identify the cylinder heads I have. I posted a few photos on a different site and someone said the following: "Those heads are the old design 215 (pre-CNC) AFR and they were designed by brownfield. (@1980’s company bought out by AFR)". It's a mystery it seems until I take them part and measure them. I asked AFR for stud to stud dimensions and or any other dimensions and they were not interested in giving me a " Blueprint". AFR did offer a solution though and that was to ship the heads to Auburn Washington to a repair facility? It's a mystery it seems until I take them part and measure them.

Rebelrouser: Thank you for the input on the cracking possibility. This was a fear of mine. Were the cracks easily visible on yours?

If anyone else on this forum who has experienced good leakdown numbers and good running engines leaking to head studs near cylinders please respond with the problem and what you did you solve it. I want the pressure to stay in the cylinder and force the piston down - Not combat my head studs/threads/washer and contaminate my oil with combustion gasses in this way.

I appreciate everyone's knowledge,

Bryan from Oregon

I really do appreciate all of your replies. I have NOT discovered any pressure from the cylinder leakdown test entering the cooling system of this engine during this test. I do appreciate the insight about the sealing options Tuner and others have mentioned in their replies and I will save those for my memory bank of solutions to future problems I may come across.

The real issue is the pressure from the cylinder is excapaing to its surrounding head studs. There appears to be a real lack of these situations documented online and thats surprising to me. I am not wanting to add a sealant to the threads of the fasteners to curb the issue. The fundamentals of this problem in my perspective is the pressure in the cylinder is somehow leaving the cylinder and leaking into a portion of the engine it does not belong and that is into the head stud provisions machined into the cylinder head casting surrounding the cylinders tested. The pressure does not do me any good there!

Danobee: I am going to have to pull this engine apart and check the surface finishes and also the head gaskets requirements for sealing for sure. I am going to look into better gasket material.

Rustbucket79 and NWHP: I am waiting on an MSD6al box to come back from repair and I will do just that - leakdown test the cylinders while the engine is at operating temp and compare the results with the cold leakdown test.

Bill: I like your idea of marking each fastener and losing half a turn then torturing and studying the relationship between then original nut position to the new.

Momus: Absolutely agree with tearing the engine down but not quite there yet. I want to form a solid plan on what parts I need before the teardown. I must wait for more room in my work area to dissasemble this engine. I have another engine in progress at the moment.

RFOLL: I did call AFR and speak with two different representatives. I sent photographs of the heads and markings to both representatives and neither can identify the cylinder heads I have. I posted a few photos on a different site and someone said the following: "Those heads are the old design 215 (pre-CNC) AFR and they were designed by brownfield. (@1980’s company bought out by AFR)". It's a mystery it seems until I take them part and measure them. I asked AFR for stud to stud dimensions and or any other dimensions and they were not interested in giving me a " Blueprint". AFR did offer a solution though and that was to ship the heads to Auburn Washington to a repair facility? It's a mystery it seems until I take them part and measure them.

Rebelrouser: Thank you for the input on the cracking possibility. This was a fear of mine. Were the cracks easily visible on yours?

If anyone else on this forum who has experienced good leakdown numbers and good running engines leaking to head studs near cylinders please respond with the problem and what you did you solve it. I want the pressure to stay in the cylinder and force the piston down - Not combat my head studs/threads/washer and contaminate my oil with combustion gasses in this way.

I appreciate everyone's knowledge,

Bryan from Oregon

-

rebelrouser

- Guru

- Posts: 1943

- Joined: Tue Sep 15, 2015 2:25 pm

- Location:

Re: Sbc leakdown test reveals leak to ARP studs threads

It was cracked in one of the cylinders the head bolt hole next to the steam hole. Not sure what bore you have but on a 400 just not a lot of thickness if the have a very big bore.Justa1time wrote: ↑Thu Jun 03, 2021 12:36 am Good evening everyone,

I really do appreciate all of your replies. I have NOT discovered any pressure from the cylinder leakdown test entering the cooling system of this engine during this test. I do appreciate the insight about the sealing options Tuner and others have mentioned in their replies and I will save those for my memory bank of solutions to future problems I may come across.

The real issue is the pressure from the cylinder is excapaing to its surrounding head studs. There appears to be a real lack of these situations documented online and thats surprising to me. I am not wanting to add a sealant to the threads of the fasteners to curb the issue. The fundamentals of this problem in my perspective is the pressure in the cylinder is somehow leaving the cylinder and leaking into a portion of the engine it does not belong and that is into the head stud provisions machined into the cylinder head casting surrounding the cylinders tested. The pressure does not do me any good there!

Danobee: I am going to have to pull this engine apart and check the surface finishes and also the head gaskets requirements for sealing for sure. I am going to look into better gasket material.

Rustbucket79 and NWHP: I am waiting on an MSD6al box to come back from repair and I will do just that - leakdown test the cylinders while the engine is at operating temp and compare the results with the cold leakdown test.

Bill: I like your idea of marking each fastener and losing half a turn then torturing and studying the relationship between then original nut position to the new.

Momus: Absolutely agree with tearing the engine down but not quite there yet. I want to form a solid plan on what parts I need before the teardown. I must wait for more room in my work area to dissasemble this engine. I have another engine in progress at the moment.

RFOLL: I did call AFR and speak with two different representatives. I sent photographs of the heads and markings to both representatives and neither can identify the cylinder heads I have. I posted a few photos on a different site and someone said the following: "Those heads are the old design 215 (pre-CNC) AFR and they were designed by brownfield. (@1980’s company bought out by AFR)". It's a mystery it seems until I take them part and measure them. I asked AFR for stud to stud dimensions and or any other dimensions and they were not interested in giving me a " Blueprint". AFR did offer a solution though and that was to ship the heads to Auburn Washington to a repair facility? It's a mystery it seems until I take them part and measure them.

Rebelrouser: Thank you for the input on the cracking possibility. This was a fear of mine. Were the cracks easily visible on yours?

If anyone else on this forum who has experienced good leakdown numbers and good running engines leaking to head studs near cylinders please respond with the problem and what you did you solve it. I want the pressure to stay in the cylinder and force the piston down - Not combat my head studs/threads/washer and contaminate my oil with combustion gasses in this way.

I appreciate everyone's knowledge,

Bryan from Oregon