Dry sump using a wet sump pan?

Moderator: Team

Dry sump using a wet sump pan?

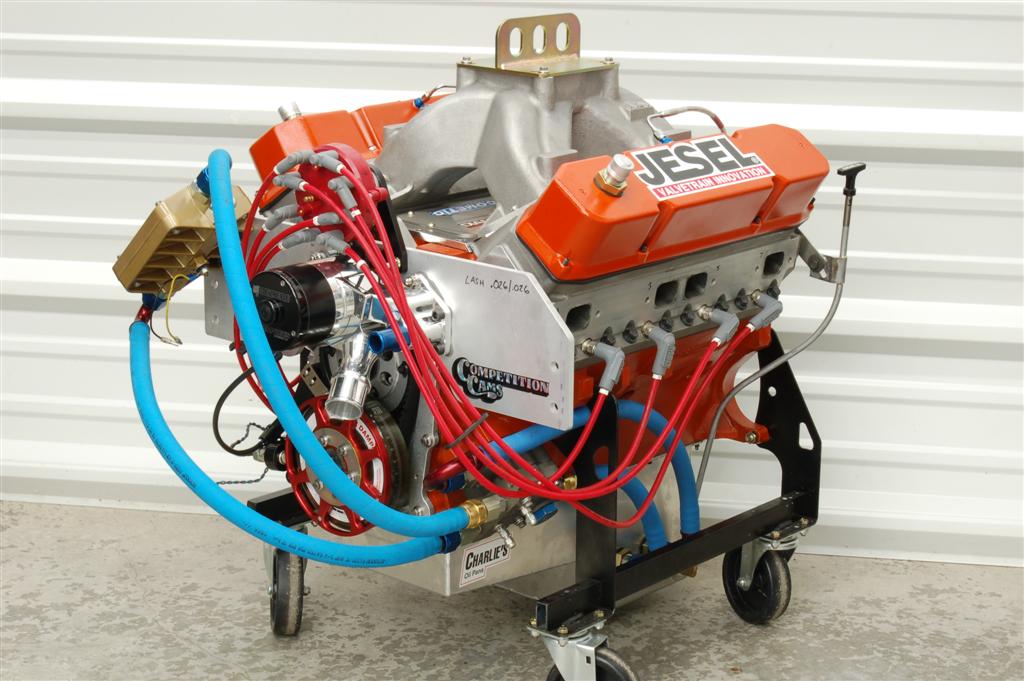

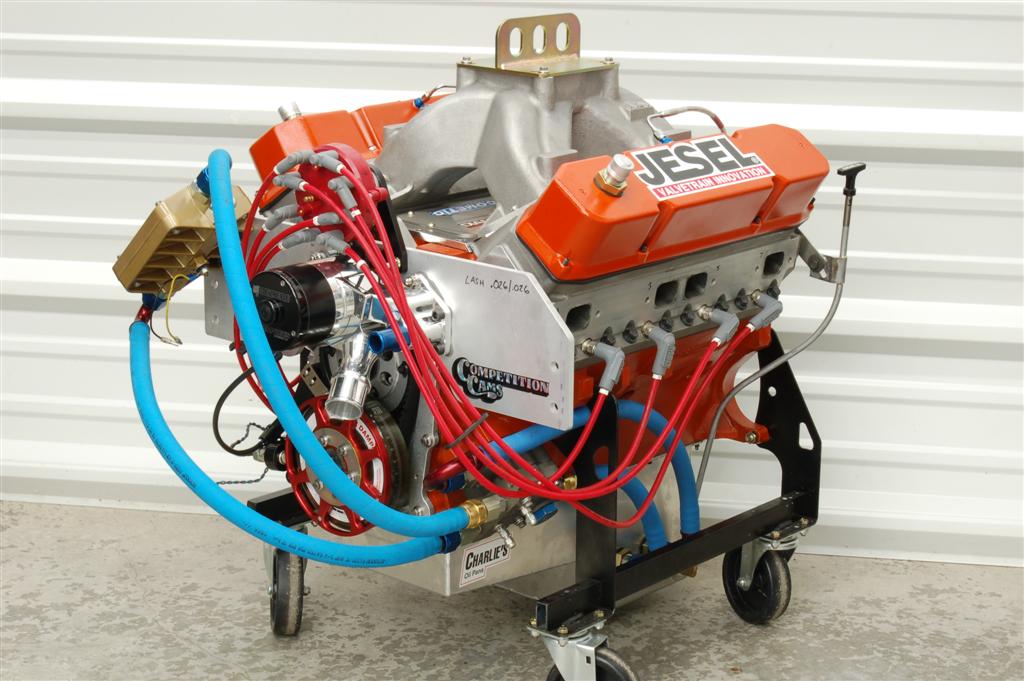

Any particular issue using a wet sump pan for a dry sump setup? I have a deep dyno pan with external #12AN pickups that I typically use with an external pump (Mopar big block). I was looking at buying a dry sump pan but it seems to me like the existing pan should work okay.

Only thing I can think of is that the pickup might be a little different in a dry sump pan but the pickups I have in my wet sump pan look a lot like the ones I've seen in dry sump pans. Basically a square box covered with a screen.

Only thing I can think of is that the pickup might be a little different in a dry sump pan but the pickups I have in my wet sump pan look a lot like the ones I've seen in dry sump pans. Basically a square box covered with a screen.

Andy F.

AR Engineering

AR Engineering

Here is a picture of the wet sump pan that I'm currently using. It seems to me that I can just remove the external oil pump from the block and hang a dry sump pump from the motor plate and then re-route the lines and I'm done. That should be an easy wet to dry comparison on the dyno. Anyone ever do that? Seems to me it will work okay, any guesses on power changes? Even with the deep pan there is probably more windage with the wet sump than with a dry sump.

Andy F.

AR Engineering

AR Engineering

-

xenginebuilder

- Expert

- Posts: 529

- Joined: Sat Aug 18, 2007 8:57 pm

- Location: MN, USA

Years ago, a Cup engine builder told me that the best pan for power was the deepest/biggest. Usually you want to lower the engine in the chassis, the dry sump allows for much closer floor of the pan, but when you are considering just max power, he told me that they built a pan 20" deep for dyno purposes in an effort to see where the point of diminishing returns was, and concluded that the bigger the better. Since you are not lowering the engine in the chassis, I think you are just fine with your existing pan and the conversion to drysump.andyf wrote: That should be an easy wet to dry comparison on the dyno. Anyone ever do that?

If you lend someone $20.00 and never see that person again, it was probably worth it.

-

Larry Heath

- Member

- Posts: 119

- Joined: Sun Nov 25, 2007 1:49 pm

- Location: South Florida

As an aside I see you are using an Oberg filter. If you are using the standard 60-micron filter element all of the most damaging wear particles are going straight through that filter. I ran an Oberg for a few years, but every time I pulled the engine down the bearings and crank showed sighs of particulate wear.

I have since gone to the Canton Racing Products filters (CM filters http://www.cmfilters.com/ ). They have a very large amount of filter area and filter down to 8-microns having a very high flow rate even at very small particle size rating. I seem to remember that the worst sizes are in the 15 to 25 micron range. The crank journals now comes out looking just polished new as apposed to a glass beaded dull gray with the Oberg filter.

Also, Ed Pink did oil pan studies a long time ago, 30 years or more, bigger and deeper makes more power. Seems I remember he had an engine on the dyno with a pan that was two feet deep and it was still making more power when he quit making the pan deeper. So long as you can be sure that oil will get to the pickups it doesn’t much matter what the size or depth of the pan is. I run a 9” deep box pan with one pickup fore and one aft on my 565, it seems to work just fine in a drag race application.

Later Larry

I have since gone to the Canton Racing Products filters (CM filters http://www.cmfilters.com/ ). They have a very large amount of filter area and filter down to 8-microns having a very high flow rate even at very small particle size rating. I seem to remember that the worst sizes are in the 15 to 25 micron range. The crank journals now comes out looking just polished new as apposed to a glass beaded dull gray with the Oberg filter.

Also, Ed Pink did oil pan studies a long time ago, 30 years or more, bigger and deeper makes more power. Seems I remember he had an engine on the dyno with a pan that was two feet deep and it was still making more power when he quit making the pan deeper. So long as you can be sure that oil will get to the pickups it doesn’t much matter what the size or depth of the pan is. I run a 9” deep box pan with one pickup fore and one aft on my 565, it seems to work just fine in a drag race application.

Later Larry

I couldn't think of any reason why a deep pan wouldn't work with a dry sump, I guess it just isn't usually done since the dry sump is there in part to lower the engine and reduce the sump.

But maybe a deep dry sump pan is the best combination possible for power production? Not only is the pan evacuated by the pump, but whatever oil is in the pan is away from the crank.

I'll give it a go and we'll see what happens. I should be able to tell pretty quickly if there is a problem by watching the sight gauge on the oil tank.

As for the Oberg, we run that for dyno tests only since it is a quick way to see if any junk is showing up. A lot of times the Oberg is a prescreen for a large 2 qt Chevy truck filter. The Oberg just picks up the big stuff and lets you ID any junk that is floating around. It usually just has shop towel lint in it which is good. Small pieces of aluminum are normal after any new parts are installed but pieces of bearing material are always a bad sign.

But maybe a deep dry sump pan is the best combination possible for power production? Not only is the pan evacuated by the pump, but whatever oil is in the pan is away from the crank.

I'll give it a go and we'll see what happens. I should be able to tell pretty quickly if there is a problem by watching the sight gauge on the oil tank.

As for the Oberg, we run that for dyno tests only since it is a quick way to see if any junk is showing up. A lot of times the Oberg is a prescreen for a large 2 qt Chevy truck filter. The Oberg just picks up the big stuff and lets you ID any junk that is floating around. It usually just has shop towel lint in it which is good. Small pieces of aluminum are normal after any new parts are installed but pieces of bearing material are always a bad sign.

Andy F.

AR Engineering

AR Engineering

-

Larry Heath

- Member

- Posts: 119

- Joined: Sun Nov 25, 2007 1:49 pm

- Location: South Florida

-

xenginebuilder

- Expert

- Posts: 529

- Joined: Sat Aug 18, 2007 8:57 pm

- Location: MN, USA

Don't pitch that Oberg yet. When you set up your drysump, you'll want to feed your pressure side through a good large free flow paper element "race" or truck type filter, but you can install the Oberg in the return line. Most of the newer pumps are internally ported on the scavenge side to a single -16, run that to the Oberg just before the tank return port. If you mount the filter just above the return height, the oil will naturally drain out as soon as the engine is shut off, you can quickly pop it apart without making a big mess check for rocks and birds and such before it gets to the tank, which will help you keep on top of your engine health and keep the tank a lot cleaner. A fairly coarse screen will do the job.andyf wrote:As for the Oberg, we run that for dyno tests only since it is a quick way to see if any junk is showing up. A lot of times the Oberg is a prescreen for a large 2 qt Chevy truck filter.

If you lend someone $20.00 and never see that person again, it was probably worth it.

Andy - You already have one of the best making your pans. Ask Charlie! When I asked him to make a dry sump pan for our latest sbc, he asked "Do you want it the same dimensions as your wet sump pans?" I responded "Make the best damn pan you can for this engine and we'll modify the chassis to make it fit!" It turned out to be 6+" deep in front and 9+" deep in the back (and makes great power).

Roger Copeland

R&R Racing

R&R Racing

I talked to Charlie and he said the same pan would work okay. He thought it would work even better if I sent it back to him for some mods to the pickup but I'll try it as is first.

I had to fabricate a bunch of parts to hang the pump on my BB Mopar engien since it doesn't appear to be a popular combination with the vendors. I bought a blank spline drive set up from Peterson and then machined it to fit a Mopar. It all seems to have turned out okay but it was a bunch of custom work.

I had to fabricate a bunch of parts to hang the pump on my BB Mopar engien since it doesn't appear to be a popular combination with the vendors. I bought a blank spline drive set up from Peterson and then machined it to fit a Mopar. It all seems to have turned out okay but it was a bunch of custom work.

Andy F.

AR Engineering

AR Engineering

The Moroso Pan I have that I believe was designed for Pro Stock truck and such almost put me on the florr with shock at it's sheer size. From memory it's 8" in the front and 9" deep in the rear. This is a 5 stage Pro Eliminator dry sump pan for a R3/W8 engine. You should be fine.

AL...

AL...

Alan Jones

It's Ok to disagree, just don't be disagreeable!

It's Ok to disagree, just don't be disagreeable!

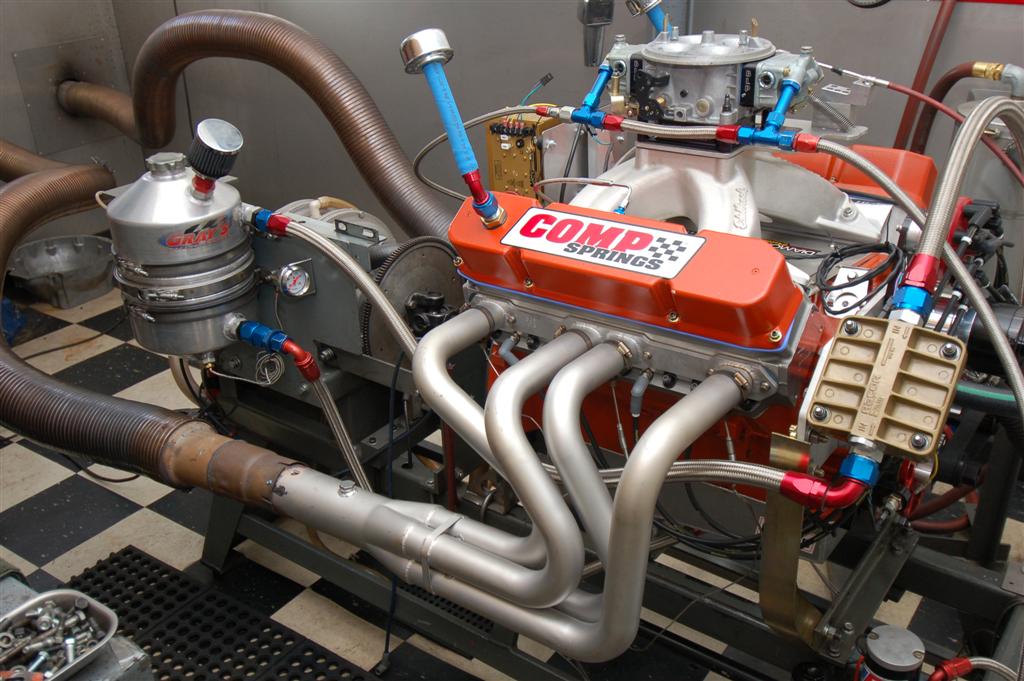

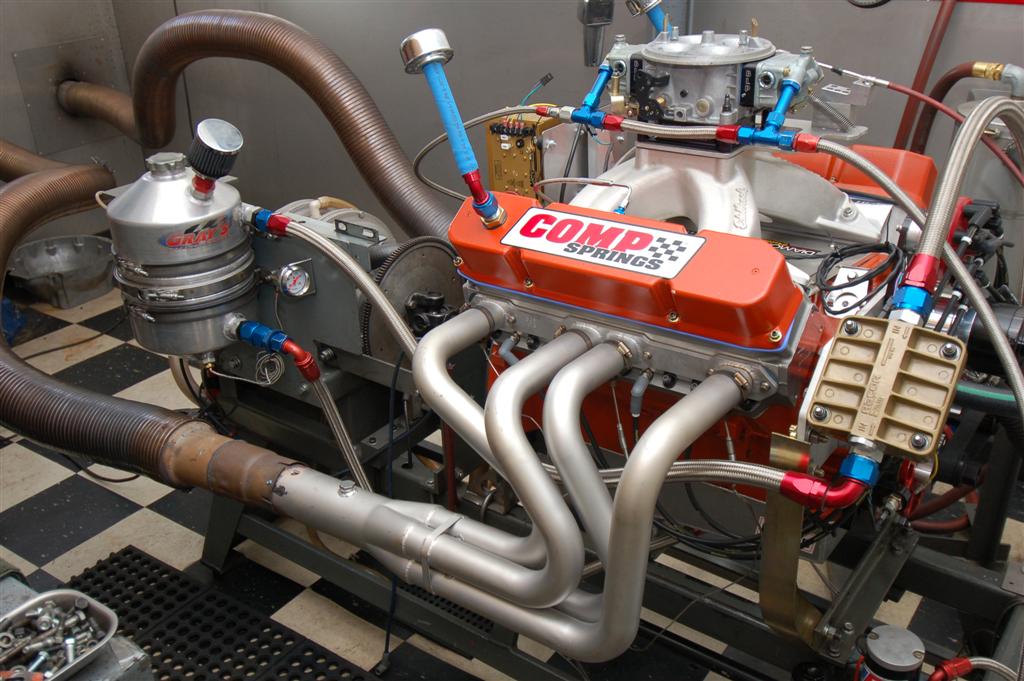

We had the motor on the dyno today with the dry sump working. Everything seemed to work just fine. Oil pressure was nice and steady in the mid-60's during the pulls and the Oberg pre-screen filter stayed perfectly clean.

Motor made about 800 hp depending on which combination we were testing. This is kind of a SpeedTalk motor with a Mike Jones cam, some billet metering plates from Mike Laws at BLP and some header input from PipeMax.

This is a 505 inch Mopar big-block with Indy EZ heads, a Mopar Performance low rise intake manifold and a 3 stage pump from Peterson. The carb is a Holley 3 circuit with the 5200 series BLP metering blocks. It sure is easy to dial in a fuel curve with the metering blocks. The intermediate circuit has pickup and discharge jets so you can go crazy with the combinations. I had to make my own lever arms for the accel pumps since the blocks are thicker than stock but that wasn't a big deal for me. Just sent a CAD program to the laser and had them in a jiffy.

Motor made about 800 hp depending on which combination we were testing. This is kind of a SpeedTalk motor with a Mike Jones cam, some billet metering plates from Mike Laws at BLP and some header input from PipeMax.

This is a 505 inch Mopar big-block with Indy EZ heads, a Mopar Performance low rise intake manifold and a 3 stage pump from Peterson. The carb is a Holley 3 circuit with the 5200 series BLP metering blocks. It sure is easy to dial in a fuel curve with the metering blocks. The intermediate circuit has pickup and discharge jets so you can go crazy with the combinations. I had to make my own lever arms for the accel pumps since the blocks are thicker than stock but that wasn't a big deal for me. Just sent a CAD program to the laser and had them in a jiffy.

Andy F.

AR Engineering

AR Engineering

Here is a picture that I took when we were loading the engine up for the dyno session. The #16 AN line goes to the Oberg pre-screen mounted on the motor plate. Then a line from there goes to the tank. There was a paper filter mounted on the pressure side of the system.

I mounted up a MSD 7AL-2 ignition box with a HVC coil on a plate mounted to the cylinder head so I could use my own ignition system rather than the dyno shop's setup. This works pretty well and lets me wire in a start retard box that they dyno shop doesn't have. I ran 37 degrees with no advance curve. Crank trigger ignition with a belt driven distributor.

I mounted up a MSD 7AL-2 ignition box with a HVC coil on a plate mounted to the cylinder head so I could use my own ignition system rather than the dyno shop's setup. This works pretty well and lets me wire in a start retard box that they dyno shop doesn't have. I ran 37 degrees with no advance curve. Crank trigger ignition with a belt driven distributor.

Andy F.

AR Engineering

AR Engineering