when are 3/4 grooved main bearings needed for bbc ?

Moderator: Team

Re: when are 3/4 grooved main bearings needed for bbc ?

A wide survey of the crank pile today it looks like (with rod UP) hole the main is in the range of 9 o-clock to 6 o-clock position, on everything.

454 or a 350 looks like about 8 to 9 o-clock.

Which means the "holes would align", at 90-180 afterTDC

In order to get them to align at 70, you would grind an oil scoop in the crank. perhaps this is what he means.

I don't doubt one position works better than another, but as for why.....I don't claim to know.

And I also don\t understand advanced.

IMO 70 atdc is MORe advanced than 90 atdc

454 or a 350 looks like about 8 to 9 o-clock.

Which means the "holes would align", at 90-180 afterTDC

In order to get them to align at 70, you would grind an oil scoop in the crank. perhaps this is what he means.

I don't doubt one position works better than another, but as for why.....I don't claim to know.

And I also don\t understand advanced.

IMO 70 atdc is MORe advanced than 90 atdc

-

Warp Speed

- Guru

- Posts: 3285

- Joined: Wed Jun 25, 2008 1:46 pm

- Location: NC

Re: when are 3/4 grooved main bearings needed for bbc ?

So, we know the SBC blocks are ok "timing' wise (about 90* atdc) but the slightly "advanced" state of the Cleveland (even closer to the magic 70* atdc) points to any "timing" issue being in the crank, and the poor block that gets blamed for the timing issue, would actually help a SBC rod feed drilling.modok wrote: ↑Mon Nov 25, 2019 7:51 pm A wide survey of the crank pile today it looks like (with rod UP) hole the main is in the range of 9 o-clock to 6 o-clock position, on everything.

454 or a 350 looks like about 8 to 9 o-clock.

Which means the "holes would align", at 90-180 afterTDC

In order to get them to align at 70, you would grind an oil scoop in the crank. perhaps this is what he means.

I don't doubt one position works better than another, but as for why.....I don't claim to know.

And I also don\t understand advanced.

IMO 70 atdc is MORe advanced than 90 atdc

Got it.........

-

swampbuggy

- Guru

- Posts: 1575

- Joined: Mon Apr 04, 2011 8:54 pm

- Location: central Florida

Re: when are 3/4 grooved main bearings needed for bbc ?

right.. Is it the crank, or the block, or both?

The next logical question then would be.....

do reverse rotation cleaveland blocks have oiling problems?

The next logical question then would be.....

do reverse rotation cleaveland blocks have oiling problems?

Re: when are 3/4 grooved main bearings needed for bbc ?

Warp Speed wrote: ↑Mon Nov 25, 2019 8:52 pmmodok wrote: ↑Mon Nov 25, 2019 7:51 pm A wide survey of the crank pile today it looks like (with rod UP) hole the main is in the range of 9 o-clock to 6 o-clock position, on everything.

454 or a 350 looks like about 8 to 9 o-clock.

Which means the "holes would align", at 90-180 afterTDC

In order to get them to align at 70, you would grind an oil scoop in the crank. perhaps this is what he means.

I don't doubt one position works better than another, but as for why.....I don't claim to know.

And I also don\t understand advanced.

IMO 70 atdc is MORe advanced than 90 atdc

The best thing you can do is build a Chrylser and prove me wrong. Evidently you don't get it. I'd need to grab a degree wheel and see if the holes actually line up at 70 or 90 degrees ATDC.

In your world you can put the oil hole in at just above the parting line and leave the feed in the crank in the same position and it will oil.

Ok.

You still can't explain why Chrysler has said for decades to run full groove mains? Could it be they KNOW the timing is off? Or are they just stupid? You figure it out.

So, we know the SBC blocks are ok "timing' wise (about 90* atdc) but the slightly "advanced" state of the Cleveland (even closer to the magic 70* atdc) points to any "timing" issue being in the crank, and the poor block that gets blamed for the timing issue, would actually help a SBC rod feed drilling.

Got it.........

-

Warp Speed

- Guru

- Posts: 3285

- Joined: Wed Jun 25, 2008 1:46 pm

- Location: NC

Re: when are 3/4 grooved main bearings needed for bbc ?

ClassAct wrote: ↑Tue Nov 26, 2019 12:00 amWarp Speed wrote: ↑Mon Nov 25, 2019 8:52 pmmodok wrote: ↑Mon Nov 25, 2019 7:51 pm A wide survey of the crank pile today it looks like (with rod UP) hole the main is in the range of 9 o-clock to 6 o-clock position, on everything.

454 or a 350 looks like about 8 to 9 o-clock.

Which means the "holes would align", at 90-180 afterTDC

In order to get them to align at 70, you would grind an oil scoop in the crank. perhaps this is what he means.

I don't doubt one position works better than another, but as for why.....I don't claim to know.

And I also don\t understand advanced.

IMO 70 atdc is MORe advanced than 90 atdc

The best thing you can do is build a Chrylser and prove me wrong. Evidently you don't get it. I'd need to grab a degree wheel and see if the holes actually line up at 70 or 90 degrees ATDC.

In your world you can put the oil hole in at just above the parting line and leave the feed in the crank in the same position and it will oil.

Ok.

You still can't explain why Chrysler has said for decades to run full groove mains? Could it be they KNOW the timing is off? Or are they just stupid? You figure it out.

So, we know the SBC blocks are ok "timing' wise (about 90* atdc) but the slightly "advanced" state of the Cleveland (even closer to the magic 70* atdc) points to any "timing" issue being in the crank, and the poor block that gets blamed for the timing issue, would actually help a SBC rod feed drilling.

Got it.........

Like a 340 that turns 8k almost every outing in a street car, and has been together almost 20 years?!? Lol

We made some mods to the oiling system, but didnt change the location of the feed hole.

And guess what? Not a full groove main anywhere!

Weird huh?!? Lol

Btw, since you hacked up your quote and reply, I was not sure who you were talking to but....

Re: when are 3/4 grooved main bearings needed for bbc ?

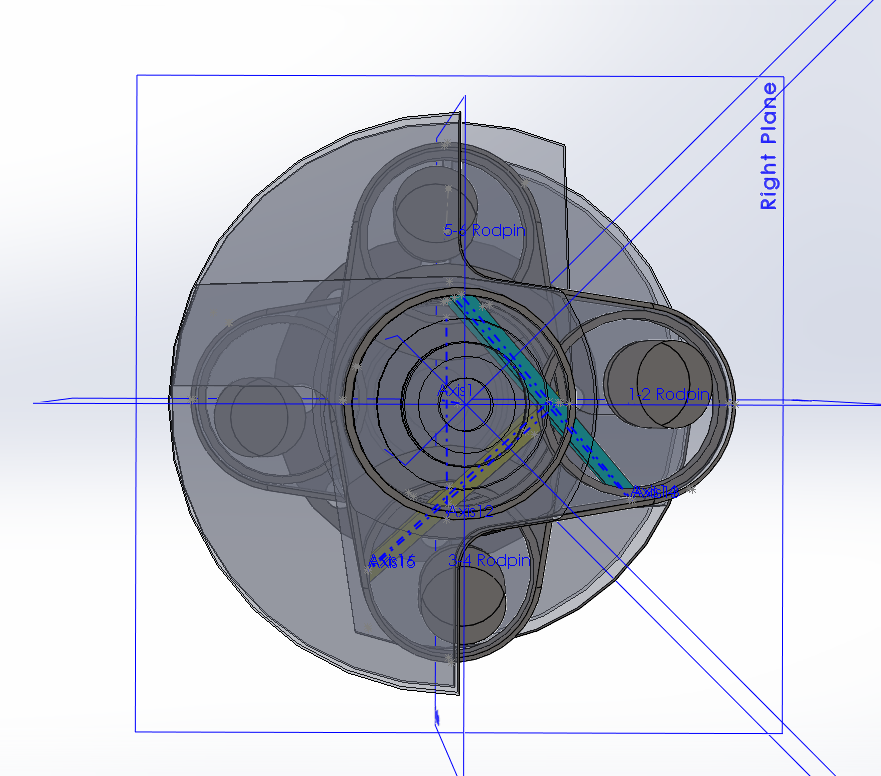

Ok, just finished "re-drilling" my CAD crank to properly represent the oil passages. My Callies and Bryant cranks are very similar to Modok's observations and an online diagram I found of an SBC crank - with the rod journal pointed vertical, the main journal hole is at 9:00 and the rod journal hole is at 3:00. The passage for Cylinder #1 is planar with Cylinder #2 which means both #1 and #2 main journals are "clocked" the same. The main feed hole in a RB Mopar and SBC is at "noon", same as on an SBC. This means that #1 oil passage is aligned with the feed hole at 45* ATDC and the #2 is at 135* ATDC. This gives each main journal hole 90* crank degrees of exposure from the bearing groove also while the rods are both on the down stroke with #2 starting on its upstroke before the passage is shut off. (this tells me oil flow is established not long after the main journal hole is exposed to the bearing groove.)modok wrote: ↑Mon Nov 25, 2019 7:51 pm A wide survey of the crank pile today it looks like (with rod UP) hole the main is in the range of 9 o-clock to 6 o-clock position, on everything.

454 or a 350 looks like about 8 to 9 o-clock.

Which means the "holes would align", at 90-180 afterTDC

In order to get them to align at 70, you would grind an oil scoop in the crank. perhaps this is what he means.

I don't doubt one position works better than another, but as for why.....I don't claim to know.

And I also don\t understand advanced.

IMO 70 atdc is MORe advanced than 90 atdc

The Callies crank has cute little scoops on the main journals and the Bryant crank does not.

So, does oiling both rods at the same time work better than trying to oil them perfectly timed to some amount of degrees ATDC? I don't know enough about this yet to make any assertions. From my small engine experience, it really doesn't take much oil spray/mist to keep a rod journal and wrist pin oiled.

To keep in the spirit of barely staying on topic, here's a pic of the Bryant crank. I need somebody to tell my why it's a good thing to create oil reservoirs in the crank journals. The crank was originally made for a TAD engine so it's supposed to handle ridiculous RPMs.

https://www.chevytalk.org/fusionbb/show ... 1983/tp/2/

https://www.chevytalk.org/fusionbb/show ... 1983/tp/2/-

swampbuggy

- Guru

- Posts: 1575

- Joined: Mon Apr 04, 2011 8:54 pm

- Location: central Florida

Re: when are 3/4 grooved main bearings needed for bbc ?

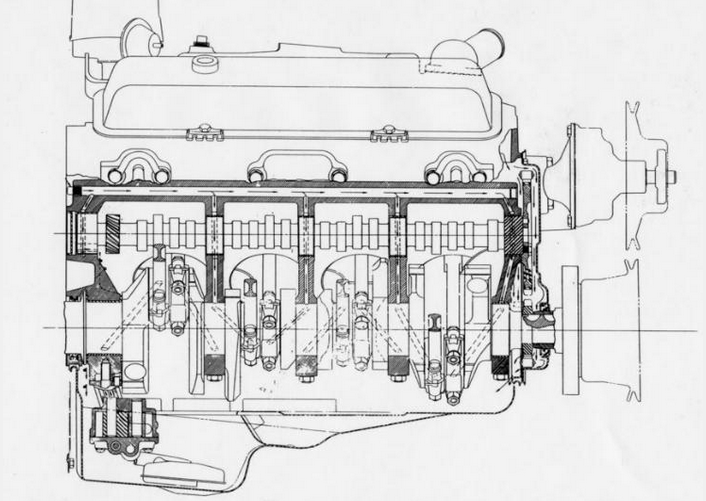

This is the way my brain thinks proper(rod bearing) oiling works. First one needs a sufficient amount of engine oil be it in a typical oil pan (or) a dry sump tank so that the oil pump NEVER draws in any air. We all know that less air (tiny bubbles) in the oil which is drawn in by the oil pump is a positive, this is (one) reason among others that a well designed Dry Sump oil system is better. The oil is forced by pressure to the main bearing groove. When the hole in the crank main journal gets to the groove in the main bearing, oil which is under (constant) pressure at and in the main bearing groove (wherever) it is located is forced into the main journal hole. The oil then moves through the internal passages of the crankshaft to the rod journal hole where it exits and the (critical) hydrodynamic wedge is formed. Comments ? Mark H.

Re: when are 3/4 grooved main bearings needed for bbc ?

I think there’s a step there missing. I think the oil in the groove has to accelerate to the surface speed of the main journal before oil gets pushed in. But I’m not 100% sure, what do you guys think?swampbuggy wrote: ↑Tue Nov 26, 2019 9:28 am This is the way my brain thinks proper(rod bearing) oiling works. First one needs a sufficient amount of engine oil be it in a typical oil pan (or) a dry sump tank so that the oil pump NEVER draws in any air. We all know that less air (tiny bubbles) in the oil which is drawn in by the oil pump is a positive, this is (one) reason among others that a well designed Dry Sump oil system is better. The oil is forced by pressure to the main bearing groove. When the hole in the crank main journal gets to the groove in the main bearing, oil which is under (constant) pressure at and in the main bearing groove (wherever) it is located is forced into the main journal hole. The oil then moves through the internal passages of the crankshaft to the rod journal hole where it exits and the (critical) hydrodynamic wedge is formed. Comments ? Mark H.

Paradigms often shift without the clutch -- https://www.youtube.com/watch?v=cxn-LxwsrnU

https://www.instagram.com/ptuomov/

Put Search Keywords Here

https://www.instagram.com/ptuomov/

Put Search Keywords Here

Re: when are 3/4 grooved main bearings needed for bbc ?

On hollow crankshafts with oil reservoirs inside:

http://www.f1-forecast.com/pdf/F1-Files ... P2_31e.pdf

http://www.f1-forecast.com/pdf/F1-Files ... P2_31e.pdf

Paradigms often shift without the clutch -- https://www.youtube.com/watch?v=cxn-LxwsrnU

https://www.instagram.com/ptuomov/

Put Search Keywords Here

https://www.instagram.com/ptuomov/

Put Search Keywords Here

-

Warp Speed

- Guru

- Posts: 3285

- Joined: Wed Jun 25, 2008 1:46 pm

- Location: NC

Re: when are 3/4 grooved main bearings needed for bbc ?

It only needs a pressure differential to flow.ptuomov wrote: ↑Tue Nov 26, 2019 9:35 amI think there’s a step there missing. I think the oil in the groove has to accelerate to the surface speed of the main journal before oil gets pushed in. But I’m not 100% sure, what do you guys think?swampbuggy wrote: ↑Tue Nov 26, 2019 9:28 am This is the way my brain thinks proper(rod bearing) oiling works. First one needs a sufficient amount of engine oil be it in a typical oil pan (or) a dry sump tank so that the oil pump NEVER draws in any air. We all know that less air (tiny bubbles) in the oil which is drawn in by the oil pump is a positive, this is (one) reason among others that a well designed Dry Sump oil system is better. The oil is forced by pressure to the main bearing groove. When the hole in the crank main journal gets to the groove in the main bearing, oil which is under (constant) pressure at and in the main bearing groove (wherever) it is located is forced into the main journal hole. The oil then moves through the internal passages of the crankshaft to the rod journal hole where it exits and the (critical) hydrodynamic wedge is formed. Comments ? Mark H.

-

Warp Speed

- Guru

- Posts: 3285

- Joined: Wed Jun 25, 2008 1:46 pm

- Location: NC

Re: when are 3/4 grooved main bearings needed for bbc ?

I can't really go too much into the oiling strategy we use, but I know one thing for sure. If the theory Classact has on oil timing were true, none of our engines would make it through a single pull on the dyno.

As I've said all along, look elsewhere for the problem, because thats NOT it!

As I've said all along, look elsewhere for the problem, because thats NOT it!

Re: when are 3/4 grooved main bearings needed for bbc ?

Sure, but how much of it? If the entire force used to accelerate the oil to the surface speed of the journal comes from the oil pressure, then by my math the pressure needed for that acceleration is equal to what is needed to push the oil from the outer orbit to the centerline of the crank. In other words, the worst case scenario is doubling of the oil pressure requirement for a cross-drilled crank.Warp Speed wrote: ↑Tue Nov 26, 2019 10:08 am"I think there’s a step there missing. I think the oil in the groove has to accelerate to the surface speed of the main journal before oil gets pushed in. But I’m not 100% sure, what do you guys think?"

It only needs a pressure differential to flow.

In practice, the supply oil pressure is not the only thing accelerating the oil to the surface speed of the main journal. Oil is viscous and there's a friction force from the crank main journal surface accelerating the oil also. What fraction comes from this friction force and what fraction has to come from supply pressure is not known to me.

I might just be completely wrong about this, but I don't see how oil can go inside the crankshaft without first being accelerated to the surface speed of the opening. In terms of high school physics, I mean.

Paradigms often shift without the clutch -- https://www.youtube.com/watch?v=cxn-LxwsrnU

https://www.instagram.com/ptuomov/

Put Search Keywords Here

https://www.instagram.com/ptuomov/

Put Search Keywords Here

Re: when are 3/4 grooved main bearings needed for bbc ?

Warp Speed wrote: ↑Tue Nov 26, 2019 10:16 am I can't really go too much into the oiling strategy we use, but I know one thing for sure. If the theory Classact has on oil timing were true, none of our engines would make it through a single pull on the dyno.

As I've said all along, look elsewhere for the problem, because thats NOT it!

Once again, the OP didn't ask about what you do. The actual question was about a 3/4 groove main bearing for a BBC. He wasn't talking about the latest, greatest oiling system you use.

The sad thing is, the oil timing issue is well known. How it's done today at the NASCAR I can't say and really don't care. Most guys on here will never deal with it.

A hydraulics engineer, who wasn't indoctrinated in automotive engineering, developed the system needed o fix the oil timing on engines where it's off.

Again, I don't know anyone, not a single guy I can think of, who actually runs RPM's at 8k or more who hasn't had Rod bearing oiling issues with the OE type oiling system. I know that many guys claimed they did/do it, but data logging proved most of them never saw the high side of 7600.

The oiling system of an OE engine is essentially the same for every brand out there, with very small differences. Yet, the SBC was the ONLY one that oiled reliably at virtually any RPM you had the balls to pay for. And none of the rest of them would even get close and to do that took a bunch of modifications and even then, reliability was a big question mark.

So take two blocks and cranks, a SBC and for fun, let's use a BB MoPar which is just as bad and set them side by each and look at the differences. Virtually no differences, except where the oil feed hole is located.

I had the good fortune to work with a local Comp racer who eventually set and reset several times his National Record. I also looked at most of his runs right off the data logger. He shifted at 9800 and crossed at 10,200-10,400 depending on conditions and clutch tuning etc. Did that with a wet sump and an oiling system that was literally untouched. His blocks didn't even have priority main oiling until he had set and ready the record several times.

You're not going to do that with any other brand.

So figure out what the difference is.

To the OP, you don't need more than a half groove bearing for a BBC. Or a SBC. Anything else, use a half groove bearing at your own risk.

-

Kevin Johnson

- HotPass

- Posts: 9391

- Joined: Tue Nov 22, 2005 5:41 am

- Location:

Re: when are 3/4 grooved main bearings needed for bbc ?

Rick! wrote: ↑Tue Nov 26, 2019 7:48 am ...

Ok, just finished "re-drilling" my CAD crank to properly represent the oil passages. My Callies and Bryant cranks are very similar to Modok's observations and an online diagram I found of an SBC crank - with the rod journal pointed vertical, the main journal hole is at 9:00 and the rod journal hole is at 3:00. The passage for Cylinder #1 is planar with Cylinder #2 which means both #1 and #2 main journals are "clocked" the same. The main feed hole in a RB Mopar and SBC is at "noon", same as on an SBC. This means that #1 oil passage is aligned with the feed hole at 45* ATDC and the #2 is at 135* ATDC. This gives each main journal hole 90* crank degrees of exposure from the bearing groove also while the rods are both on the down stroke with #2 starting on its upstroke before the passage is shut off. (this tells me oil flow is established not long after the main journal hole is exposed to the bearing groove.)

The Callies crank has cute little scoops on the main journals and the Bryant crank does not. ... I need somebody to tell my why it's a good thing to create oil reservoirs in the crank journals. ...

Cute little scoops: see Meernik SAE paper cited earlier; a modification of his general idea; a functional design flourish. The reverse design is sometimes employed to facilitate outflow into the bearing clearance at the rod journals.

Oiling diagrams: one-shot oiling. The reaction force of the right-handed-rotation of outer passage walls accelerates the oil (raises dynamic pressure). I am assuming that they could be used counterclockwise as well though I would be leery of running minimal oil supply pressure (empirically test). Better to use a bespoke drilling change.

If the oiling passages and chamber are purged of any air prior to starting the engine, the reservoir/chamber will serve as a dynamically pressurized reservoir via centripetal acceleration and reaction force from the chamber walls. By communicating chambers or passages, the supply from the main only needs to replenish what is lost to flow through the bearing clearance and will be assisted in flowing from the mains supply. There would be some chance of cavitation in the passage, I suppose, if the lubricant vapor pressure was not low enough and in-flow insufficient. Engineers seem to be proficient enough at maths to ward against this.

Honda left out the bit about the reservoirs. Maybe it is considered common knowledge so they focused on explaining friction welding before it became illegal the following year.

Back to work.

Driving Force Online: BREAKING NEWS—Ohio Governor Signs SEMA-Supported Vehicle Freedom Bill Into Law!