Does anyone know if distance between main journals 4 and 5 is the same as between journals 1 and 2?

I've got a two piece crank and a vernier and it's not quite the right equipment to make the measurements so I can complete the CAD model of it.

Thanks.

Mopar RB Crank Journal Spacing

Moderator: Team

-

BillK

- Guru

- Posts: 1756

- Joined: Wed Aug 26, 2009 8:30 pm

- Location: Beautiful Southern Maryland

- Contact:

Re: Mopar RB Crank Journal Spacing

Rick,

I have several cranks at the shop. I will try to remember to measure a couple of them in the morning.

I have several cranks at the shop. I will try to remember to measure a couple of them in the morning.

Bill Koustenis

Advanced Automotive Machine

Waldorf Md

www.enginerepairshop.com

Advanced Automotive Machine

Waldorf Md

www.enginerepairshop.com

-

SchmidtMotorWorks

- Vendor

- Posts: 11003

- Joined: Mon Apr 11, 2005 2:30 am

- Location: CA

Re: Mopar RB Crank Journal Spacing

Most Race cranks are.

The OEM stuff was all over the place.

The OEM stuff was all over the place.

Helping to Deliver the Promise of Flying Cars

Re: Mopar RB Crank Journal Spacing

What is a two piece crank and why not just check the mains in the block, if the spacing is different on the crank the block will be spaced accordingly.

Re: Mopar RB Crank Journal Spacing

Thanks for the measurements, Bill, much obliged.

Diodedog, "two-piece" is another way of saying broken crank. The block, along with a new Bryant billet crank, is in Immokalee this weekend.

-

SchmidtMotorWorks

- Vendor

- Posts: 11003

- Joined: Mon Apr 11, 2005 2:30 am

- Location: CA

Re: Mopar RB Crank Journal Spacing

What is your goal?

To make one?

Helping to Deliver the Promise of Flying Cars

Re: Mopar RB Crank Journal Spacing

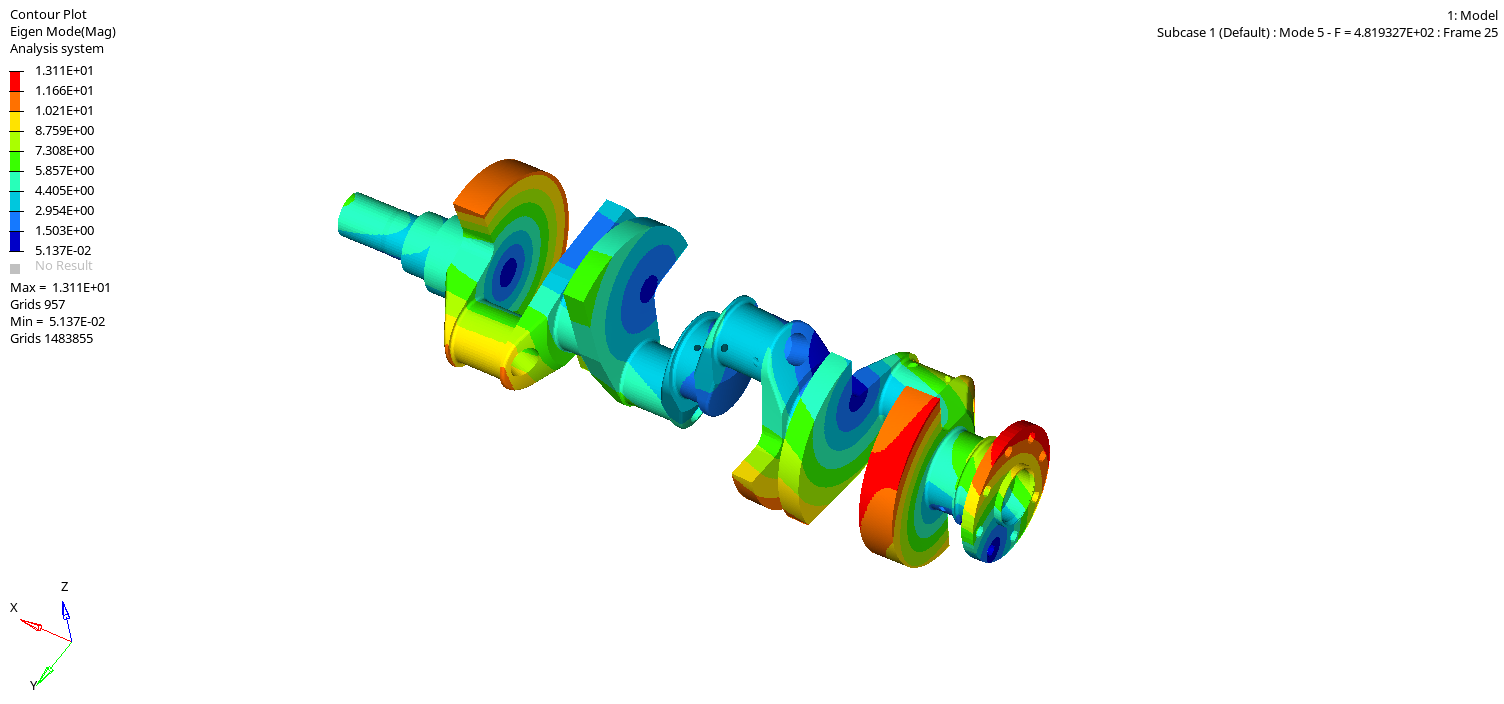

My goal is to have a reasonably accurate CAD model so I can do a bunch of modals on it to understand what rpm the crank shouldn't be run. By reasonably accurate, I mean it will have the right physics but not be perfect enough to to send to CAM and make a crank. (It could be but there is minimal data I can find on the interwebs to place mains 1 and 5 perfectly and to mimic the angles of the cuts on the pork chops.)

Free-free modals are already done. Now I need to CAD up an ATI balancer and create a physically correct TC (inertia-wise) and simulate the mains and finish the analysis stuff. That will drop the torsional mode shown by a bit, I just need to know by how much as it's right at a shift point currently.

-

SchmidtMotorWorks

- Vendor

- Posts: 11003

- Joined: Mon Apr 11, 2005 2:30 am

- Location: CA

Re: Mopar RB Crank Journal Spacing

Are you also including the attached objects?Rick! wrote: ↑Tue Nov 19, 2019 7:41 amMy goal is to have a reasonably accurate CAD model so I can do a bunch of modals on it to understand what rpm the crank shouldn't be run. By reasonably accurate, I mean it will have the right physics but not be perfect enough to to send to CAM and make a crank. (It could be but there is minimal data I can find on the interwebs to place mains 1 and 5 perfectly and to mimic the angles of the cuts on the pork chops.)

Free-free modals are already done. Now I need to CAD up an ATI balancer and create a physically correct TC (inertia-wise) and simulate the mains and finish the analysis stuff. That will drop the torsional mode shown by a bit, I just need to know by how much as it's right at a shift point currently.

Are you hoping to optimize angles of the CWs through modal analysis?

Helping to Deliver the Promise of Flying Cars

Re: Mopar RB Crank Journal Spacing

I always just go kinda high on the RPM then fix the broken parts and back off a few hundred RPM’s...LOL

NHRA SS/G

1970 AMC AMX - 390 4-speed

Advanced Clutches - Red Line Racing Cams

1970 AMC AMX - 390 4-speed

Advanced Clutches - Red Line Racing Cams